HTML

-

A7N01高强铝合金具有低密度、高比强度、高比刚度和良好的加工及焊接性能等特点,在航空、航天、交通运输等领域具有广泛的应用前景,在促进高速列车车体结构轻量化的过程中也具有独特优势[1-7]。然而采用传统的焊接方法,如熔化极惰性气体保护焊(melt inert-gas,MIG)焊接,对高强铝合金车体结构进行焊接时,易产生气孔、裂纹和夹杂等缺陷,并且焊接效率低,因此,急需采用先进的焊接技术解决上述问题[8-11]。激光-MIG复合焊接作为一种新型焊接技术,能够将激光与电弧两种热源有机结合,从而改善铝合金的焊接适应性,提高铝合金的焊接效率和质量,是目前国内外高强铝合金焊接研究的热点[12-20]。

本文中以6mm厚的A7N01铝合金板材为研究对象,采用激光(碟片式激光器)-MIG复合焊接工艺对其进行焊接,探究全熔透焊接条件下,焊接工艺参量对焊缝成形、接头力学性能的影响,分析接头的微观组织。

-

试验采用的焊接材料为A7N01铝合金板,规格为150mm×75mm×6mm,焊丝采用ER5356铝合金焊丝,直径1.2mm。母材及焊丝成分如表 1所示。

element Al Si Fe Cu Mn Mg Cr Zn Ti 7N01 balance 0.0030 0.0035 0.0020 0.0070 0.0200 0.0030 0.0500 0.0020 ER5356 balance 0.0025 0.004 0.0010 0.0020 0.0450 0.0010 0.0010 0.0006 Table 1. Chemical compositions of A7N01 aluminum alloy and ER5356 welding wire (mass fraction)

-

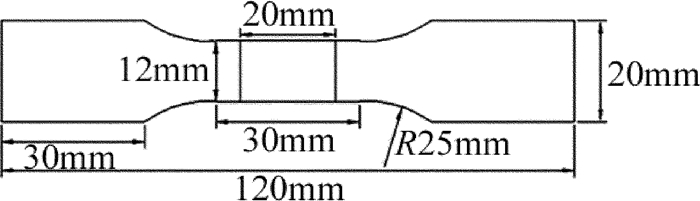

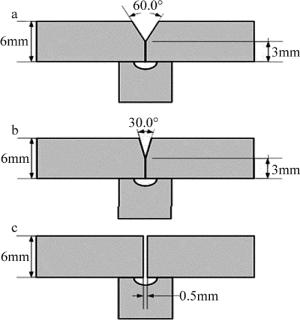

在6mm厚的7N01铝合金试样板上进行激光-MIG焊接试验,通过改变焊接工艺参量,研究激光功率和焊接速度对焊缝成形的影响关系,试验工艺参量如表 2所示。试验中通过改变激光功率和焊接速度,探究其对焊缝熔宽、熔深、余高以及宏观形貌的影响。此外,为优化焊缝成形,得到表面成形良好,并且底部成形连续的焊缝,焊接试样板底部采用纯铜衬垫板。3种坡口形式如图 1所示。分别是:Y型60°坡口,3mm钝边;Y型30°坡口,3mm钝边;I型坡口,0.5mm间隙。

numbering groove type laser power/

kWwire feed speed/

(m·min-1)welding speed/

(m·min-1)arc power/

kWline energy/

(kJ·m-1)1# no groove 2.5 8.5 0.9 2.812 354.13 2# 3.5 8.5 0.9 2.812 420.80 3# 3.0 8.5 0.9 2.812 387.47 4# 3.0 8.5 1.2 2.812 290.60 5# 3.0 8.5 0.75 2.812 464.96 6# Y-shaped 60° 3.0 9.0 1.0 3.028 361.68 7# Y-shaped 30° 3.0 9.0 1.0 3.028 361.68 8# 0.5mm clearance 3.0 9.0 1.0 3.028 361.68 Table 2. Welding test process parameters

Figure 1. Groove form a—Y-shaped 60°, 3mm blunt edge b—Y-shaped 30°, 3mm blunt edge c—I-shaped, 0.5mm clearance

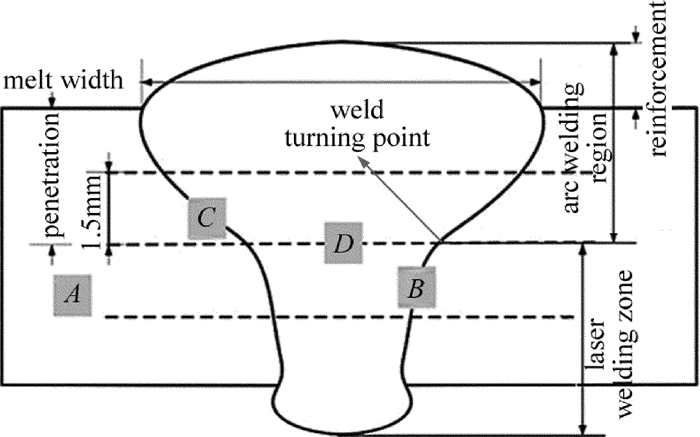

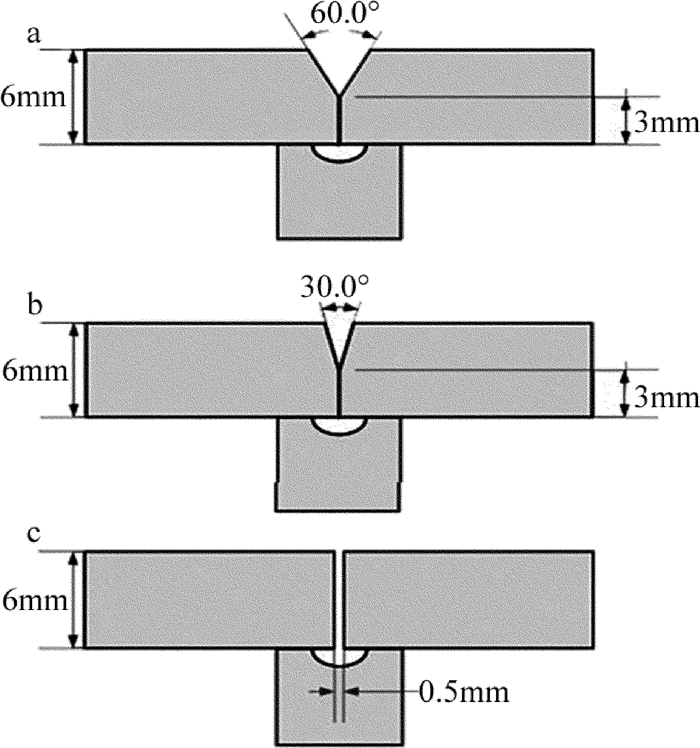

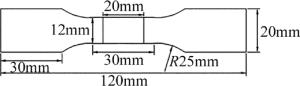

为尽量避免气孔、夹杂等缺陷,焊前对试样板进行酸碱洗,用刮刀清理母材表面的氧化膜,之后用无水乙醇清洗母材表面,清除表面油污。焊后沿垂直于焊缝方向制备金相试样,经打磨抛光后用Keller试剂进行腐蚀(Keller试剂配比为V(HF):V(HCl):V(HNO3):V(H2O)=2:3:5:90)。在金相显微镜下,观察焊缝截面,并测量熔深与熔宽和余高。采用GP-TS2000M型拉伸机,进行接头拉伸测试,拉伸试样尺寸如图 2所示。焊缝截面示意图如图 3所示,显微组织选取位置如图 3中的A, B, C, D点位置,其中焊缝转折点为激光与电弧焊接作用区域分界线,由于焊接底部,采用纯铜衬垫板强制成形,故由焊缝转折点深度,代替焊缝熔深做近似分析。图中虚线为硬度打点位置,分别在焊缝转折点、近上表面、近下表面距焊缝转折点1.5mm处。

-

激光-MIG复合焊接试验的焊接系统,主要由激光器、机器人(KUKA KR60)、MIG焊机组成,如图 4所示。激光器为Trumpf-Trudisk 10002型碟片激光器,如图 5所示。激光波长为1030nm,最大连续输出功率为10kW,光束质量为8mm·mrad,功率稳定性±1%,准直焦距200mm,聚焦焦距300mm,传输光纤芯径400μm。保护气采用纯度99.99%的氩气,气体流量为14L/min。焊接过程中,采用激光前置的方式,激光与电弧夹角为35°,离焦量为-2mm,光丝间距为1mm。试验过程中的电弧输出采用一元化控制。

1.1. 试验材料

1.2. 试验方法

1.3. 试验设备

-

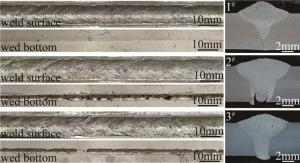

在激光-MIG复合焊接过程中,激光功率的大小对焊缝成形有重要影响。为实现单道对接熔透焊接,激光功率需要达到一定的值。通过改变激光功率,保持其它参量不变的情况下进行对接焊接,焊接参量如表 2所示,焊后接头宏观形貌与焊缝横截面,如图 6所示。根据试验结果,在激光功率2.5kW时,由于激光的功率密度较小,工件表面的熔深较浅,未能焊透试样板,如图 6中1#所示。在激光功率3.5kW时,随着激光功率的增大,工件表面的激光功率密度增大,此时,工件表面被加热到蒸发温度以上,通过形成的压力以及不断形成的金属蒸汽,激光束在工件表面形成了焊接小孔,具备了深熔焊接特性,与电弧复合作用后形成较大的熔深,激光功率越大,所形成的金属蒸汽越多,小孔内压力越大,熔深将越大。然而,由于激光功率过大,热输入过大导致焊缝过熔透,焊缝底部产生大量孔隙,焊缝质量过差,如图 6中2#所示。在激光功率3.0kW时,焊缝表面鱼鳞纹明显,无咬边、塌陷等缺陷,焊缝焊趾处,过渡平缓,焊缝成形质量较好,如图 6中3#所示。此外,焊缝底部虽熔透,但个别位置间断且底部焊道边缘不平直,工艺参量需进一步优化。可见,激光-MIG复合焊接焊缝熔深及其熔透状态,主要取决于激光功率,随着激光功率的提高,焊缝熔深趋于线性增大。可见,6mm厚的7N01铝合金在不开坡口的情况下进行对接焊接时,采用3kW的激光功率,能够获得单面焊透的试样。

-

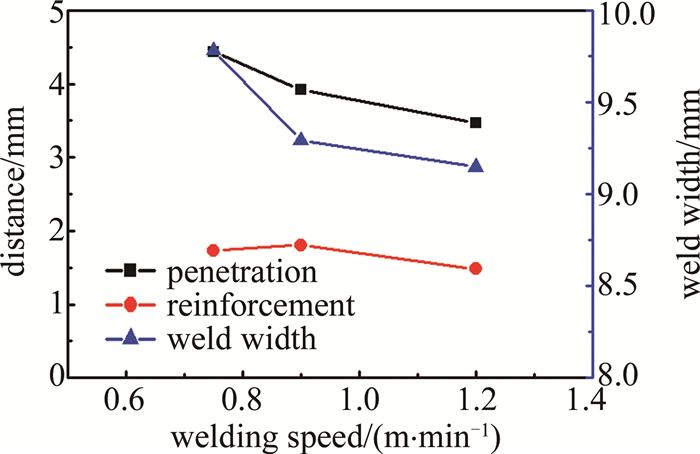

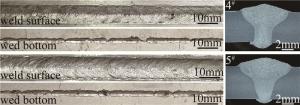

在激光-MIG复合对接焊接过程中,焊接速度将直接影响焊接接头单位热输入,从而对焊缝成形产生影响,故可通过改变焊接速率研究其对焊缝成形的影响,根据不同焊接速率下线能量大小优化工艺参量,其焊接参量如表 2所示。在激光功率3.0kW的前提下,分别采用0.90m/min, 1.20m/min, 0.75m/min的焊接速率,焊后接头宏观形貌及焊缝横截面,如图 6中3#和图 7中4#,5#所示,焊缝熔深、熔宽、余高结果,如图 8所示。实验表明,在3.0kW的激光功率下,焊缝表面均形成了明显的鱼鳞纹,随着焊接速率的降低,焊缝表面光洁度上升,鱼鳞纹致密,焊道弧度平滑,但焊缝底部成形不连续,可见,焊接速率对焊缝底部成形的影响较小。通过分析焊缝熔深、熔宽、余高的结果可知,焊接速率对焊缝熔深和熔宽有直接影响,随着焊接速率的增大,熔深与熔宽均线性减小,当焊接速率为0.75m/min时,表面成形较好,但熔宽过宽,如图 7中5#所示。此外,焊缝余高受焊接速率与送丝速率的综合影响,当焊接速率增大时,其焊接热输入增大的同时,单位时间内的送丝量也降低,导致余高的变化较小,当焊接速率为1.20m/min时, 焊缝余高略有降低,且焊缝中心不平滑。综上可见,在焊接速率为0.90m/min时,即焊接线能量约387kJ/m时获得的焊缝,其表面成形较好。

-

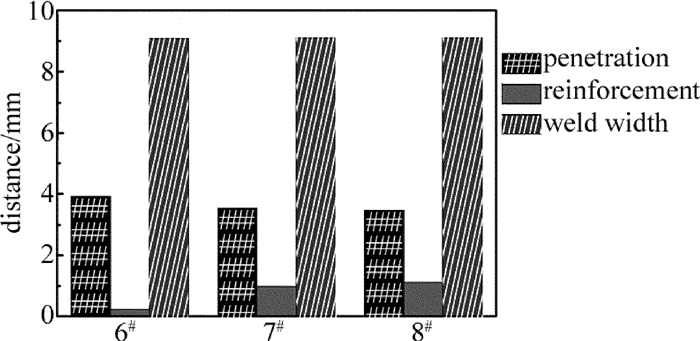

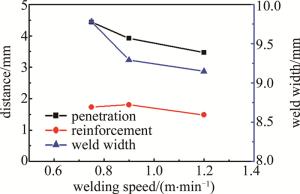

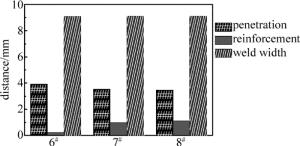

在保持线能量基本一致的前提下,实验中采用了3种坡口形式焊接,坡口形式如图 1所示,焊接参量如表 2所示,即送丝速率为9.0m/min,焊接速率为1.0m/min,线能量为362kJ/m,焊后接头宏观形貌及焊缝横截面如图 9所示。此外,坡口形式与熔深、余高、熔宽的关系如图 10所示。实验结果表明,采用Y型60°坡口和Y型30°坡口时,焊缝底部成形连续且焊道平直稳定,焊缝底部成形较好,如图 9中6#和7#所示。其中,双边60°坡口的焊缝,其熔深较大而余高较小,由于其焊缝表面间隙过大,焊丝填入量较小,焊缝产生了轻微咬边;采用双边30°以及0.5mm间隙的焊缝,其表面成形较好,焊缝熔宽、熔深和余高相差不大,而采用0.5mm间隙坡口的焊缝,其底部虽连续但焊道不平直,个别位置熔透性较差,焊缝质量不及Y型坡口,如图 9中8#所示。总体而言,采用Y型双边30°坡口的焊缝成形较好,焊接质量较好。

2.1. 激光功率对焊缝成形的影响

2.2. 焊接速率对焊缝成形的影响

2.3. 坡口形式对焊缝成形的影响

-

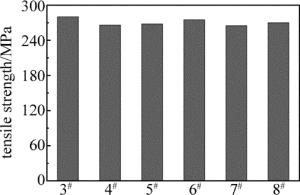

将拉伸试件按照GB/T16865-2013的检测标准,在拉力试验机上进行拉伸试验,其在不同焊接参量下平均抗拉强度及延伸率如表 3所示,用Origin绘制柱状图如图 11所示。可见,6种焊接参量下平均抗拉强度相近,均在260MPa~280MPa范围内,拉伸性能比较稳定,平均抗拉强度为271MPa,达到母材的60%;平均断后伸长率为4.3%,达到母材的48%。其断裂位置均在焊缝中心位置,如图 12所示。分析为铝合金在进行激光-MIG复合焊接时,气孔主要集中在焊缝中心以及熔合线附近,其中焊缝中心的大直径不规则气孔,对抗拉强度及焊后延伸率的影响较大,焊缝中心及熔合线附近的气孔是焊接接头的薄弱位置,易发生断裂。

numbering 3# 4# 5# 6# 7# 8# average base metal tensile strength Rm/MPa 280 266 268 275 265 270 271 454 break elongation A/% 4.0 4.5 5.5 4.5 3.5 4.0 4.3 9.0 Table 3. Average tensile strength and elongation after fracture under each welding parameter

-

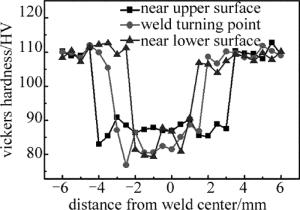

对于优化后的接头,沿垂直焊缝方向在近上表面、焊缝转折点、近下表面3种不同位置测量接头硬度,硬度值的分布如图 13所示。由图可见,3种位置处的显微硬度分布特征相似,整体上呈“U”型分布,在焊缝中心硬度较低,在熔合线附近硬度陡然上升,到母材硬度趋于平稳,母材硬度均值为109.2HV。此外,近上表面焊缝中心位置的平均硬度为87.3HV,中部及近下表面焊缝中心位置的平均硬度为83.6HV,略低于近上表面的硬度,整体焊缝平均硬度为85.4HV。这是因为激光匙孔”失稳在焊缝中部及底部易产生气孔,气孔附近的硬度较低,使底部焊缝平均硬度减小;另一方面,由于焊缝底部强制成形的衬垫板,阻碍了熔池底部金属液体的流动,使焊缝底部组织分布不均,从而降低了硬度。

-

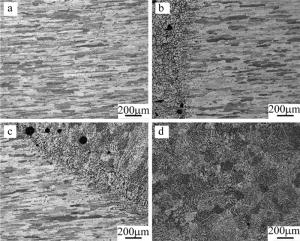

A7N01铝合金激光-MIG复合焊接接头微观组织,如图 14所示。母材区晶粒为平行于轧制方向的带条状组织,晶粒分布均匀,如图 14a所示。热影响区靠近熔合线的晶粒,由于受热循环作用,使晶粒发生了一定程度的长大,但仍保留了条带状组织的基本特征,其组织末端与母材区分不明显。由于该区受热会析出固溶相,其硬度强度会有所降低,塑性增加,如图 14b所示。焊缝熔合区组织如图 14c所示,该区域位于焊缝边缘,温度梯度较大,在熔合线靠近焊缝方向,形成了垂直于熔合线的粗大柱状晶组织,并沿焊缝中心向等轴晶区转变。由于激光-MIG复合焊接的熔池冷却速度快,其内部由于氧化物夹杂和微量水分子而产生的氢气泡短时间来不及溢出,易产生工艺类氢气孔,严重影响焊缝性能和质量。图 14d为焊接接头的焊缝区,由图可知,焊缝区组织属于典型的急冷铸态组织,母材与焊丝熔化后在焊缝中心形成等轴晶,该区易产生冶金类气孔。

3.1. 焊缝力学性能分析

3.1.1. 焊缝拉伸性能分析

3.1.2. 焊接接头的显微硬度

3.2. 接头截面形貌及其显微组织分析

-

本文中采用激光-MIG复合焊接技术对A7N01铝合金板进行了焊接。

(1) 对6mm厚的A7N01铝合金板进行激光-MIG复合焊接,当激光功率为3.0kW、送丝速率为9.0m/min、焊接速率为1.0m/min时,采用Y型30°坡口能够得到表面成形良好,且底部成形连续的焊缝。

(2) 根据焊缝成形分析可知,激光功率对熔深有直接影响,激光功率越大,熔深越大;焊接速率对焊缝熔宽和熔深的影响较大,对余高的影响较小,焊接速率越大,焊缝熔宽和熔深越小,焊缝余高略有增加;焊缝成形对坡口形式的适应性较好,其显微组织和力学性能相近。

(3) 优化后的复合热源焊接接头的平均抗拉强度为271MPa,达到母材的60%;平均断后伸长率为4.3%,达到母材的48%;焊缝中心硬度为85.4HV,达到母材的78%,且焊缝近上表面的硬度略高于中部及近下表面的硬度。

(4) 根据显微组织分析可知,母材为轧制态带状组织;热影响区晶粒粗化硬度强度有所降低;熔合线区晶粒为柱状晶,易产生工艺类氢气孔;焊缝区晶粒为等轴晶,易产生冶金类气孔。

Map

Map

DownLoad:

DownLoad: