HTML

-

目前,铜合金在现代制造业中占有重要地位,在阀门[1-2]、管道设备[3-4]、阀芯[5]等过流部件中有着广泛的应用。众所周知,过流部件中经常出现腐蚀失效的现象,为了满足应用的需要,铜合金材料的过流部件应具有良好的稳定性和耐腐蚀性。目前,提高材料耐蚀性能的手段有很多,如加入铝、铅、镍等金属元素改变合金的组织[6-7],对材料表面进行电镀层[8]和涂层[9]等,但是这些方法都相应提高了加工工艺难度和成本, 因此,简单经济的激光冲击强化(laser shock peening, LSP)技术在强化铜合金材料表面得到应用。

LSP是一种先进的表面强化技术,通过纳秒激光产生的超高压应力来提高金属材料表面的力学性能,从而改善金属材料的疲劳性能[10]、耐磨性[11]和耐腐蚀性[12]等。SUN等人研究发现, LSP可以改善ANSI 304不锈钢焊接件在空蚀后的损伤,并且LSP诱导的残余压应力是改善空蚀损伤的有效保证[13]。ZHANG等人研究证明了LSP可以使钢质材料表面区域细化到纳米尺度的晶粒,从而增加了材料的硬度[14]。并且,LSP在表面粗糙度相对较低的钢表面层中产生了较高的压缩残余应力,从而抗疲劳性能得到改善[15]。同时,许多研究表明:材料硬度的变化是反映强化能力的重要指标,硬度的增加伴随着耐蚀性能的提高[16-17]。因此,LSP是一种通过提高材料表面硬度、细化晶粒、诱导残余应力[18]来提高材料的耐腐蚀能力[19]的有效技术。

本文中通过纳秒脉冲激光对铜合金的基础材料h62黄铜板进行激光冲击强化,采用超声波空蚀试验机和电化学工作站对h62黄铜进行空蚀实验和电化学腐蚀实验,研究质量损失、显微组织、表面形貌、硬度和金相组织等来表征LSP对黄铜材料耐蚀性能的影响。

-

样品材料为厚度1.5mm的h62黄铜板,样品的化学成分(质量分数)为:w(Cu)≤0.62,w(Fe)≤0.0015,w(Pb)≤0.0008,w(Sb)≤0.00005,w(Bi)≤0.00002,其余为Zn。样品工作面面积为30mm×30mm,用不同目数(200#~1500#)的水砂纸打磨,放入无水乙醇用超声波清洗,后用吹风机冷风风干并备用。

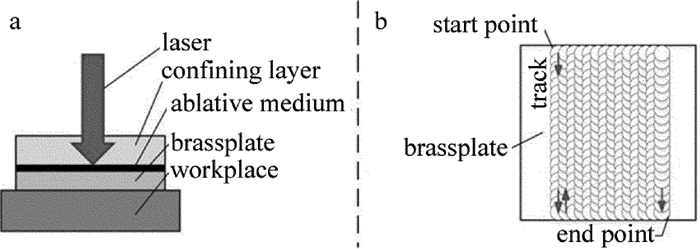

用高能密度纳秒脉冲激光(波长1064nm,脉宽7ns)冲击强化黄铜表面。本文中主要研究的是不同的能量LSP对黄铜耐蚀性能的影响,通过大量实验确定LSP的工艺参量如下:重复频率为6Hz,激光光斑直径为1.5mm,搭接率为50%[20],加工路径如图 1所示。实验中使用了一系列激光脉冲能量(0.2J,0.4J,0.6J),为了防止灼伤样品表面和提高激光能量的吸收, 用厚度40μm的黑铝箔作为吸收层。一定刚性的约束层比弹性约束层能更有效地提高激光冲击波的峰值压力[21],K9玻璃具有相当高的强度和刚度,强化冲击效果要好于水约束层,所以采用厚度为4mm的K9玻璃作为约束层,来增强等离子体的向下冲击压力[22]。最后,用超声波清洗的方法对含LSP的黄铜试样进行清洗,并用吹风机对试样进行冷风干燥并备用。

-

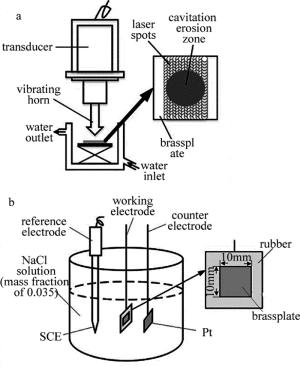

采用超声波空蚀试验机对有无LSP处理的黄铜样品进行空蚀实验。在室温下,振幅杆顶端对准样品的中心并浸泡在蒸馏水中产生气泡及微射流射向黄铜样品的工作面。黄铜样品表面与振幅杆尖端的距离为2mm。以25℃的去离子水为介质进行持续至少4h的空蚀实验。传感器的频率和峰值分别为20kHz和25μm。空蚀过程如图 2a所示。

Figure 2. a—schematic diagram of cavitation erosion experiment b—schematic diagram of electrochemical testing

通过电化学工作站,研究在质量分数为0.035的NaCl溶液中,对有无LSP处理的黄铜样品进行电化学腐蚀测试,如图 2b所示。在电化学测试中,溶液温度保持在室温,参考电极为饱和甘汞电极(saturated calomel electrode, SCE),对应电极为铂箔(Pt)。一组用不同能量(0J, 0.2J, 0.4J, 0.6J)LSP处理的样品用铜线连接,并分别用703胶和704胶进行封装并留出尺寸为10mm×10mm的工作面。采用Tafel外推法,从极化曲线来研究黄铜样品对抗电化学腐蚀的能力。

1.1. 样品及LSP实验

1.2. 空蚀和电化学腐蚀实验

-

图 3a是随着时间的变化,黄铜样品空蚀累积质量损失图。从图中可以看出,随着时间的增加,每个参量的样品累积质量逐渐增加。与未经LSP处理的黄铜样品对比,经LSP处理的黄铜样品累积质量损失减少。并且,随着能量的增加,空蚀累积质量损失降低。此外,空蚀4h后,未经LSP处理的黄铜样品累计质量损失为15.3mg, 经0.6J LSP处理的黄铜样品累积质量损失为4.1mg,0.6J LSP处理使黄铜累积质量损失缩小了大约4倍。

Figure 3. a—cumulative mass loss of brass sample after cavitation erosionb—cavitation incubation period and maximum cavitation rate of brass sample

图 3b为未经LSP处理和0.6J LSP处理的黄铜样品空蚀孕育期与最大空蚀速率柱状图。由图可知,未经LSP处理的黄铜样品的空蚀孕育期为1.5h,经0.6J LSP处理的黄铜样品孕育期为3h, 空蚀孕育期延长了2倍。另外,未经LSP处理的黄铜样品最大空蚀速率比0.6J LSP处理的大。因此,经LSP处理的黄铜样品比未经LSP处理的黄铜样品具有更好的抗空蚀性能,并且随着能量的增加,黄铜样品抗空蚀性能越好。

-

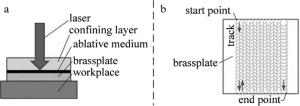

图 4a为经不同能量LSP处理的黄铜样品表面硬度分布图。每组数据测试5个点,并取平均数。从图中可以看出,空蚀后,未经LSP处理的黄铜样品硬度最小,经0.6J的能量LSP处理后的硬度最大。具体地来说,未经LSP处理的黄铜样品表面的平均硬度为125.4HV,经0.2J LSP处理的黄铜样品表面的平均硬度为136.6HV,经0.4J LSP处理的黄铜样品表面的平均硬度为147.5HV,经0.6J LSP处理的黄铜样品表面的平均硬度为162.3HV。

图 4b为不同能量LSP处理后黄铜样品的横截面硬度分布曲线图。每组数据测5个点,并取平均数。未经LSP处理的黄铜样品硬度值从表面到内部均匀分布。经0.2J LSP处理的样品硬度值从表面的139HV增加到0.1mm深度的143HV,在0.1mm~0.5mm深度上逐渐降低,0.5mm深度以下的和未强化的样品硬度分布相同,大约为123HV。经0.4J LSP处理的样品硬度值从表面的151HV增加到0.1mm深度的157HV,然后逐渐降低到0.5mm深度和未强化的黄铜样品硬度分布相同。经0.6J LSP处理的样品硬度值从表面的168HV增加到0.2mm深度的172HV,然后降低,到0.5mm后和未强化黄铜样品硬度分布相同。从图中可以知道,LSP处理黄铜样品强化硬度升高的表层大约为0.5mm厚。所以,在LSP处理黄铜样品产生的强化层内,随着LSP处理能量的增大,横截面硬度也增大。硬度的变化能反映材料的强化效果,硬度的增加可以说明其抗空蚀能力的提高[23]。由图 4可知,随着激光强化能量的提高,黄铜表面硬度和一定深度方向上的截面硬度都相应增加,因此LSP处理黄铜样品表面提高其抗空蚀性能。

-

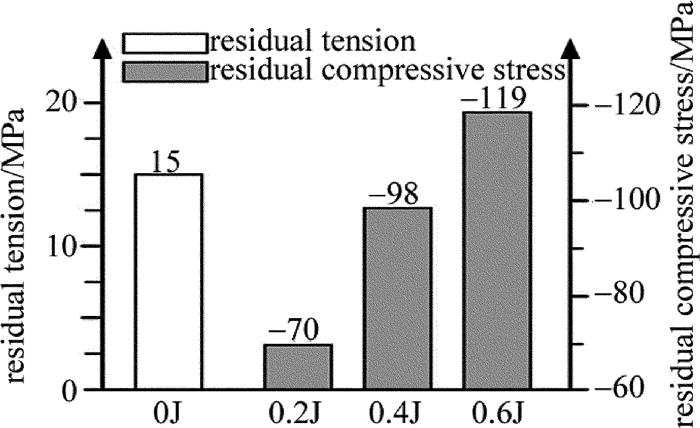

图 5是不同能量LSP处理后的黄铜样品表面残余应力图。取黄铜经不同能量冲击强化区域的3个点测量其残余应力, 并取其平均值。从图中以看出,未经激光强化处理的黄铜残余应力整体上是拉应力状态。残余拉应力经常会使材料失效,从而被当作疲劳失效的主要原因[19]。然而经LSP处理后黄铜样品表面的残余应力从拉应力变为压应力,最大残余压应力出现在0.6J LSP处理的黄铜样品表面,为-119MPa。此外,从图中可以看出, 残余压应力随着激光强化处理能量的增加而变大。图 6是有无LSP处理后的黄铜样品表面的金相组织图。从图 6中可以看出,LSP处理后的黄铜样品表面的晶粒比较细小,强化细化的晶粒尺寸大小在25μm~40μm之间,未强化的区域晶粒尺寸大小在35μm~70μm之间,从而LSP处理对黄铜样品表面晶粒有一定的细化作用。

所以,LSP处理样品表面添加一个大于其表面屈服应力的冲击力,使黄铜表面发生塑性变形,促使晶粒细化,并诱导黄铜产生残余压应力[24],即有效地将残余拉应力变为残余压应力。晶粒细化和残余压应力能抑制材料产生裂纹,延缓微裂纹向材料内部延伸[25-26],这也就能延长腐蚀过程中裂纹产生和扩张的时间,从而提高了材料的耐腐蚀性能。

-

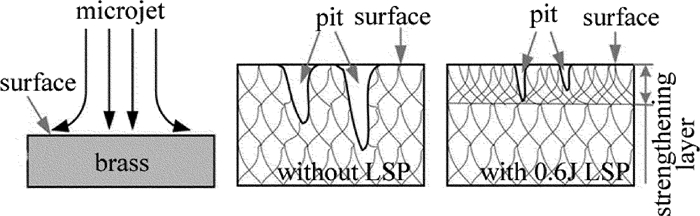

图 7为空蚀1.5h后黄铜样品经0.6J LSP处理和未经LSP处理的表面形貌SEM图片。从图 7a中可以看出,未经LSP处理的黄铜样品表面起伏比较明显,裂纹较多且产生大量的空蚀坑。从图 7d中可以看出,经0.6J LSP处理的黄铜样品表面在空蚀1.5h后较为平整,产生少量且较小的空蚀坑,裂纹还未形成,这些与LSP处理改善样品力学性能有着密切的联系。上面说到LSP处理细化了黄铜样品表面的晶粒,并且LSP处理产生的冲击力由于约束层的作用向下传导,促使黄铜表面塑性变形,形成一层细化层,即强化层。

图 8是黄铜样品表面空蚀原理图。经LSP处理的样品具有一层强化层,由于晶粒细化,不易使微裂纹向下扩张,从而强化的样品表面的空蚀缺陷更小,与上面实验所得吻合。并且在上述讨论中,未经LSP处理的黄铜样品比经0.6J LSP处理的黄铜样品硬度低,由此可以得出黄铜样品的空蚀破坏要先发生在较软的表面组织部位。LSP处理诱导黄铜表面残余压应力的产生,促使晶粒细化,从而提高了黄铜样品的塑性和韧性,可以有效地抵抗样品材料表面裂纹的产生,延长了空蚀孕育期,减缓了样品空蚀速率,从而提高了黄铜样品的抗空蚀能力。

-

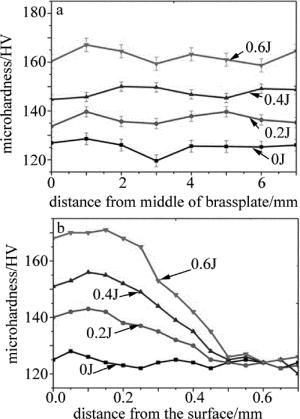

图 9为黄铜样品经不同能量LSP处理后的极化曲线。纵坐标为对电流I取对数。黄铜的电化学极化曲线由阴极区和阳极区两个部分组成,采用塔菲尔外推法,得到黄铜的腐蚀电流为1.74μA,腐蚀电位为-0.291V,0.2J、0.4J和0.6J, LSP处理后的黄铜样品的腐蚀电位分别为-0.266V, -0.247V和-0.236V, 腐蚀电流与未处理的样品相比没有规律性的变化,从而只对腐蚀电流进行分析。由于腐蚀电位是反映材料在热力学方面的腐蚀难易程度,腐蚀电位越大,耐腐蚀性能越好,所以从热力学角度来看,本组黄铜样品的耐腐蚀性为:0.6J>0.4J>0.2J>0J。因此,LSP处理可以提高黄铜样品的耐腐蚀性能,并且随着LSP的能量增大,其耐腐蚀性能越好。

2.1. 空蚀质量损失结果与分析

2.2. 表面和截面硬度测试及分析

2.3. 残余应力测试和晶粒细化及分析

2.4. 形貌观测与分析

2.5. 电化学塔菲尔极化曲线与分析

-

随着LSP处理能量的增加,黄铜样品表面硬度和一定深度的截面硬度都增加,强化产生的塑性变形使晶粒细化,诱导产生残余压应力,从而使黄铜样品空蚀累积质量损失减小,空蚀孕育期增加,最大空蚀速率降低。故LSP处理提高了黄铜样品的抗空蚀性能,且随着LSP处理能量的增大,抗空蚀性能越好。

随着LSP处理能量的增加,黄铜样品电化学腐蚀电位逐渐增加,而腐蚀电流没有较明显的变化。从热力学角度分析,腐蚀电位的增加意味着耐腐蚀性能越好,从而LSP处理可以提高黄铜样品的耐腐蚀性能。

Map

Map

DownLoad:

DownLoad: