HTML

-

自第1台红宝石激光器产生以来,激光技术一直在迅猛发展,激光技术的应用领域也越来越广泛,比如工业加工、激光切割焊接以及医疗美容等领域[1-4]。在某些特殊领域中,激光器的输出功率仍然不能满足实际需求,比如船舶制造业、军事国防领域[5-6]。将多路激光通过合束器合成单路激光出射,合束后激光功率将大大提升。光纤激光器有诸多优点,比如光束质量好、散热性好、性能稳定等,在各个领域均有广泛的应用,利用滤光片对光纤激光进行光谱合成是提高激光功率的有效途径之一, 但在高能激光连续入射至光学元件时,光学元件吸收激光能量后会产生热形变,而且形变量随着激光出射功率和激光辐照时间的增加而增加,从而对光束质量造成的影响也越明显[7-8]。已有的研究表明,熔融石英基片在高能激光连续辐照下会产生明显的热形变,一定程度上恶化光束质量。PENG等人用有限元仿真软件对变形镜的热形变面形进行了分析,分析了变形镜的形变特点对高能激光初始相位的影响[9]。CHENG等人提出了近场波面畸变的计算方法,进一步分析了近场波面畸变对高能激光远场光斑特性的影响[10]。

本文中利用COMSOL有限元分析软件,建立了在连续高能激光辐照下熔融石英基片热形变分析模型,并针对基片在不同的夹持方式下的热形变进行了比较分析。此外,还利用VirtualLab软件定量分析了熔融石英基片热形变对光束质量的影响。

-

石英玻璃不仅具有良好的物理特性,比如硬度高、穿透性好,还具有优良的化学性能,比如较高的熔点、耐热冲击力强,在温度较高的环境下工作性能稳定,对从紫外线到近红外波段的光具有优良的透射率,所以很多光学系统的窗口材料和滤光片的基底材料都是石英玻璃[11]。

假设入射激光为高斯光束,并以5°入射角入射,相应的光强分布为:

式中,I0为激光功率密度,w为束腰半径, x, y分别为相应的坐标。

当熔融石英基片被高能激光辐照时,基片吸收激光能量受热升温,此时研究基片的温度场,可采用傅里叶热传导理论,研究基片与激光相互作用时产生的温度场分,1维热传导方程[12]为:

式中,ρ为密度;c为比热容;κ为热传导系数;T为温度;z为与材料表面垂直的方向(轴向);t为时间;Q(z, t)为热源函数。

在COMSOL有限元分析软件中,可根据熔融石英的吸收系数来建立相应的热源,以等效热源的方式模拟材料对激光的吸收。热源函数为:

式中,R为反射系数,α为材料对激光的吸收系数,I为激光强度。基片材料具体参量如表 1[13]所示。

wavelength λ=1.315nm waist radius w=140mm length and width of substrate L=300mm ambient temperature T0=298.15K density ρ=2.21g·cm-3 heat capacity C=746J·kg-1 ·K- 1 thermal coefficient of expansion β=0.51×10-6 ℃-1 laser power density P=3.2481×107W·m-2 thickness of substrate H=40mm melting point Tmelt =1700℃ reflectivity R=0.035 thermal conductivity κ=1.38W·m -1·K-1 absorption coefficient α=0.19×10-3cm- 1 Young’s modulus E=7.26×1010Pa Table 1. Parameters used in simulation

-

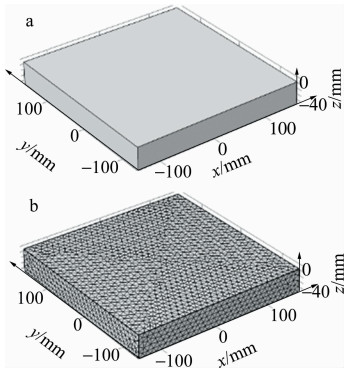

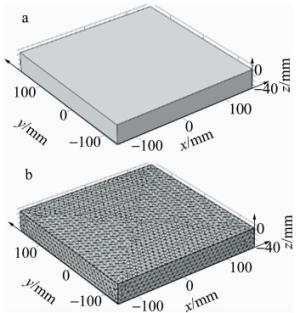

首先,建立熔融石英基片的有限元分析物理模型,如图 1a所示,基片尺寸参量为300mm×300mm×40mm;为了使仿真结果更接近解析解的同时提高计算效率,采用自由四面体单元对其进行网格划分,最大单元尺寸为6mm,最小单元尺寸为0.06mm,最大单元增长率为1.3曲率因子为0.2,如图 1b所示。

-

基片受热产生的形变主要由3个原因引起的:(1)基片吸收激光能量后沿轴向的线膨胀;(2)受热升温过程中产生的热应力造成的面形变化;(3)不能自由膨胀造成的挠曲形变,主要原因是基片被固定时周边受限[14]。所以,基片的夹持方式对基片的热变形有很大的影响,从而也会引起光束质量的变化。在实际实验操作中,常常采用机械方法固定镜片,这种情况下,对基片热形变的分析主要是分析热弹性体的边界条件效应。

下面用有限元分析软件COMSOL来分析2种不同固定方式下基片的受热形变,3种不同的固定方式分别为夹板固定、三周固定和四周固定。在实际实验中,考虑到基片大小较大,单点夹持基片会使基片受力不均匀,从而导致基片产生的热形变是无规律的,固本论文不研究单点固定方式。

-

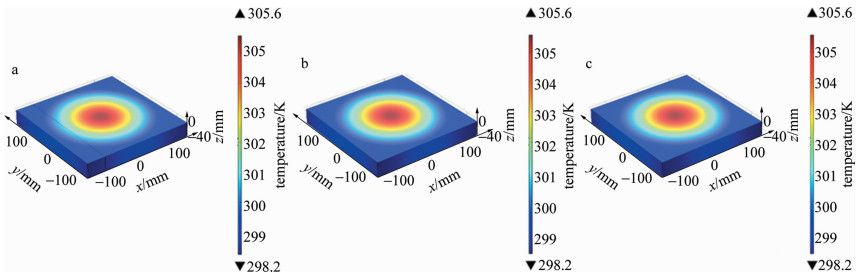

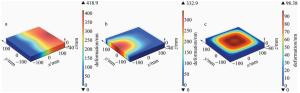

假设基片受激光辐照时间为20s,光斑直径为280mm, 环境温度为298.15K,基片的吸收系数为0.19×10-3cm-1。图 2给出了激光辐照20s后,不同夹持方式下基片表面的温度分布。图 2a为夹板固定情况下基片表面温度分布,图 2b为三周固定情况下基片表面温度分布,图 2c为四周固定情况下基片表面温度分布。可以看出,在采取3种不同夹持方式下,基片表面温升是一样的,且基片表面温度分布与入射光斑形状相似,基片表面最高升都为7.45℃。

-

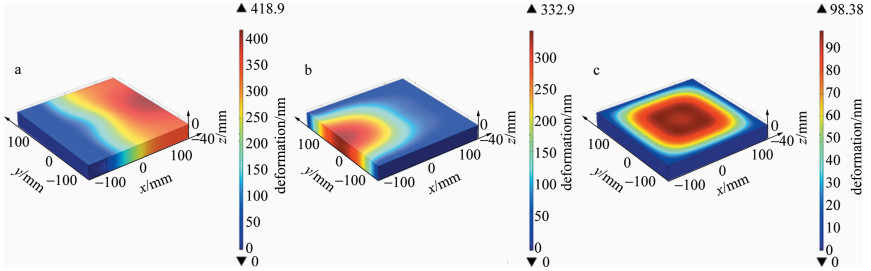

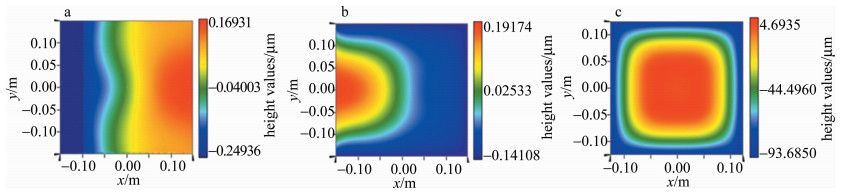

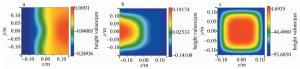

按照不同的夹持方式,设置了不同的边界条件,利用COMSOL进行分析,得到不同夹持方式下基片的热形变图。图 3所示为高能激光在基片工作20s时基片的形变图。由图 3a可知, 当基片采用夹板固定方式固定时,基片受热形变峰谷(peak-to-valley, PV)值为418.90nm, 且由于边界条件的影响,形变往自由面方向延伸,最大形变量在夹板夹持所在区域的对面。由图 3b可知,当基片采用夹三周固定方式时,基片受热形变PV值为332.90nm, 且由于边界条件的影响,最大形变量在唯一没有被边界条件限制的一周附近。由图 3c可知,当基片采用四周固定方式固定时,基片受热形变PV值为98.38nm。此时边界条件是均匀对称的,且由于激光呈高斯型分布,中心能量高,四周能量低,因此而此时基片的形变从中心往外呈递减的趋势。

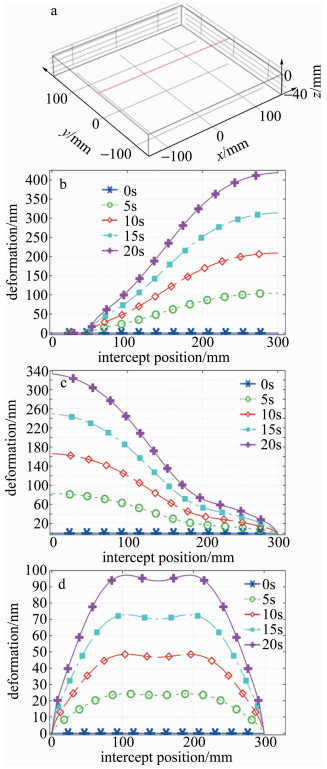

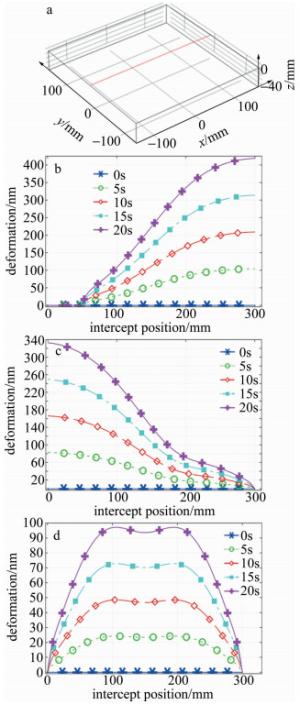

为了进一步说明基片形变与入射激光工作时间的关系,沿x轴方向在基片中心位置取一条截线(见图 4a),并对截线不同位置的形变进行仿真, 仿真结果如图 4b~图 4d所示。

由图 4b~图 4d可知,随着激光作用时间的增加,基片形变量也呈递增趋势。当采用夹板夹持和三周夹持方式时,形变量都是沿着x轴方向递增或者递减;采用四周夹持方式时形变量最大值并不出现在基片中间位置,而是在离中心位置45mm处,且左右两边呈对称状态,出现这个现象的原因可能是激光以一定的角度入射到镜面上;由于基片采用四周固定方式,x轴和y轴方向仿真条件相同,因此, y轴方向截线的形变与x轴仿真结果相同。

2.1. 夹持方式

2.2. 温度场分布

2.3. 热形变分布

-

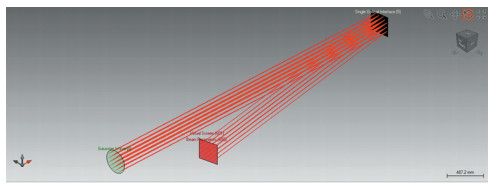

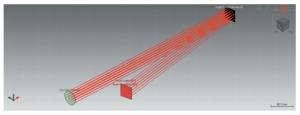

为了研究基片发生热形变后对于光束质量的影响,基于VirtualLab构建了符合上述条件的光路系统,用探测器记录更换不同夹持条件下的基片时最终传输到探测器里光束的光束质量。

搭建的光路图如图 5所示。

为了研究高斯光束经不同的面形的基片反射光的光束质量,将上节中2种由不同夹持方式引起的不同的热形变导入到VirtualLab里,仿真得到的面形如图 6所示。

由图 6可以看出,由VirtualLab仿真得到的面形形变分布与图 3是一致的,且PV值分别为418.67nm, 332.82nm, 98.38nm,与图 3中显示的418.90nm, 332.90nm, 98.38nm几乎一致。

运行光路传输结果,得到探测器检测到的光束质量结果,为了更直观地比较不同面形引起光束质量变化的情况,首先将光直接打到一个无面形形变的基片上,然后再更换不同的面形,分别得到光束质量如表 2所示。

sheet shape of the substrate beam quality factor Mx2 My2 plane 1.0036 1.0037 sheet shape of splint fixation 1.4571 1.0408 sheet shape of tricyclic fixation 1.2624 1.0061 sheet shape of boundary fixation 1.0064 1.0065 Table 2. Beam quality in different base sheet shapes

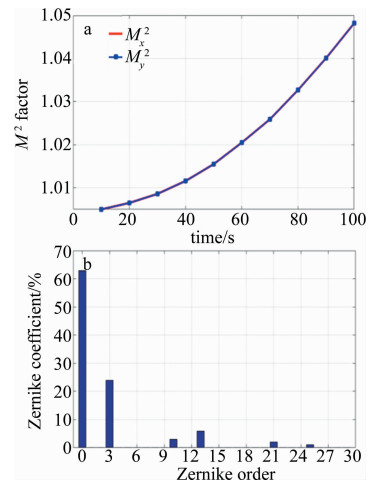

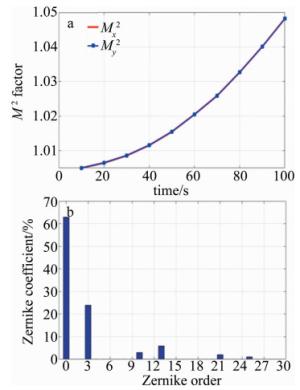

比较3种不同的夹持方式,发现采用四周固定的方式,热形变量是最小的,且对光束质量的影响也是最小的。考虑到基片较大,为了使基片在使用过程中受到较小而均匀的压力的同时保证基片工作面不受损伤[15],最好采用四周夹持的方式固定基片。为了进一步研究采用四周夹持方式时,基片热形变对光束质量的影响,将激光辐照时间延长至100s, 并绘制出光束质量随时间的变化图,如图 7a所示。

Figure 7. a—variation of beam quality with time b—the first 30 order Zernike coefficients of substrate thermal deformation surface

由图 7可以看出,随着激光辐照时间增加,光束质量因子M2(无量纲)也在逐渐变大。因为基片受激光辐照时间越长,表面形变量越大,导致光束质量下降,但光束质量下降并不严重。为了更好地分析光束质量下降的原因,进一步对采用四周夹持的基片热形变面形进行Zernike多项式分解,得到前30阶Zernike系数, 其结果如图 7b所示。

从图 7b可以看出,对于基片的热形变面形,除了含有较大的平移项(第0项)和离焦项(第3项)外,还包含了少量的球差项(第10项)和其它高阶项。在Zernike多项式中,平移项代表波前的平均光程差,离焦项表示波前的高斯或近轴特性。而离焦量对M2影响很小,只有少部分的球差会对光束质量有较大的影响,所以光束质量下降并不严重。

-

利用COMSOL有限元分析软件建立了熔融石英基片的热形变分析模型,研究了激光辐照下基片的温升和热形变,重点分析了基片的热形变的特点及其对光束质量的影响,并比较了不同夹持方式下基片的热形变差异。在本文计算示例中,不同的夹持方式对基片热形变的影响程度有所不同:采用四周夹持方式时,基片表面形变量相对较小;采用夹板夹持或者三周夹持时,热形变量都较大。基片的热形变会对光束质量造成影响,激光辐照时间越长,热形变量越大,对光束质量影响越大。采用四周夹持方式时基片热形变引起的像差中平移项和离焦项占比重较大,对光束质量影响较小。

Map

Map

DownLoad:

DownLoad: