HTML

-

热电偶温度传感器由于结构简单、性能稳定、测量范围广、操作方便,成为应用最广泛的温度传感器[1]。随着新型快速响应、大量程热电偶的不断研发,如何准确获取传感器的动静态性能指标尤为迫切。在传感器选型及系统搭建时,必须获取传感器动静态性能指标,这是保证无失真测试重要环节[2]。时间常数是热电偶动态性能指标之一[3]。针对于热电偶时间常数的测试通常有:(1)投入实验法。采用机械动作将热电偶从室温插入恒温场中,其优点在于价格低廉、方法简单,但是温度场一般是恒温油或者恒温水,温度上限较低, 且误差受机械动作的影响较大[4-6];(2)热风洞法。利用高温快速气流对热电偶进行时间常数测量,但是热风洞的造价昂贵、风洞的体积巨大[7-8];(3)激波管法。利用高、低压力界面导通的瞬间在压力界面处形成一个阶跃的温度突变,但是它所持续的时间较短,经过大量实践表明,当平稳温度的时间大于5倍时间常数τ时,才可以测出较为准确的时间常数值[9-10]。以上方法重点是在热电偶测温端形成一个定量的温度阶跃,尤其对于具有快速响应特点的热电偶,阶跃温度信号的质量直接影响到所测得热电偶时间常数的准确性。

由于激光具有极高的能量,可以在极短的时间内在材料表面形成局部的高温,因此可以为时间常数的测量提供较为理想的温度加热源。本系统采用大功率、上升时间短的半导体激光器作为激励源,以波兰VIGO公司PDI-4型探测器对热电偶测温端的实时温度进行在线监测、反馈[11-13],在热电偶表面产生符合要求的温度阶跃,进而实现了热电偶在高温件下的时间常数测试[14-15]。本文中针对该测试系统在常规的比例-积分-微分(proportion-integral-derivative,PID)控制过程中,控温过程中热电偶表面的温度变化与激光器的输出变化展开研究,为控制算法及控制效果优化提供理论依据。

-

本系统是以STM32F429开发板为主控制器,热电偶时间常数激光测试系统硬件原理图如图 1所示。主要由主控制器、激光器驱动电源、半导体激光器、光学整形单元、无像差椭球面共轭聚焦反射镜、被校热电偶、高速红外辐射测温模块、模/数转换器(analog-to-digital converter,ADC)、信号调理电路、数据采集模块、屏蔽箱等组成。

根据激光器手册可知,激光器工作电压在20V左右,激光器的输出功率与输入电流呈线性关系。激光器驱动电源的主要功能是通过输入脉宽调制后的脉宽调制波(pulse width modulation, PWM),经内部电路转换为高频变化的输出电流,只需通过编程输入不同占空比的PWM波,即可控制激光器输出不同的加热功率。本激光器为连续激光器,激光器输出激光时间即PWM波总时长。无像差椭球面共轭聚焦反射镜的两个焦点具有无像差的特点,利用高速红外辐射测温模块的响应速度远远快于被校热电偶,因此, 在其中一个焦点处可以准确地测量出另外一个焦点处的温度。本热电偶时间常数测试系统将被校热电偶与高速红外辐射测温模块分别放置于无像差椭球面共轭聚焦反射镜的两个共轭焦点处,高速红外辐射测温模块对被校热电偶表面的温度辐射值进行采集,经过ADC转换后输送到主控制器中,主控制器通过PID反馈控制输出不同占空比的PWM波控制激光器输出激光,对位于焦点处的被校热电偶进行加热,最终在被校热电偶测温端实现定量的温度阶跃,进而通过采集被校热电偶的响应曲线来获取被校热电偶的时间常数。

-

在热电偶时间常数测试中,通常热电偶传热方程忽略了热电偶测温端导热传热量及辐射传热量。

式中,Q1为测量端储热量,Q2为测量端对流传热量,ρ为测量端密度,c为测量端比热容,V为测量端体积,T1为测量端表面温度,T2为介质温度,h为对流换热系数,A为测量端换热面积。

设$\tau = \frac{{\rho cV}}{{hA}} $,根据(1)式和(2)式整理可得:

假设时间t=0,T1=T1, 0(T1, 0为零时刻测量端表面温度), 可得:

式中,C为积分常数,由初始条件决定。

根据(6)式可得,当t=τ时,热电偶指示温度达到阶跃温度的63.2%,即热电偶时间常数的定义[16-20]。

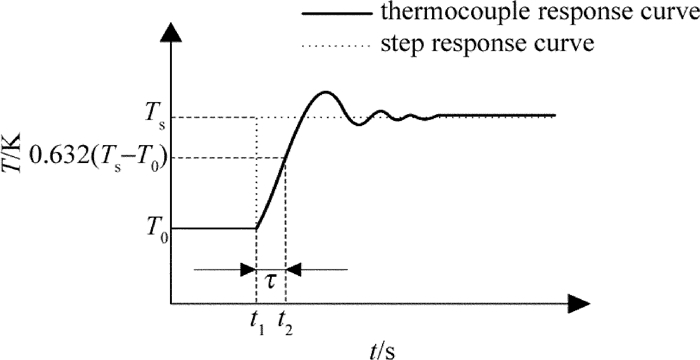

热电偶时间常数测试方法基本都是通过在热电偶测温端形成一个定量的温度阶跃变化,进而在热电偶输出端获取其响应曲线,热电偶理想响应曲线如图 2所示, 横坐标为时间t,纵坐标为温度T。t1为起始时刻,t2为热电偶指示温度达到阶跃温度的63.2%时的时刻,T0为起始时刻热电偶的温度,Ts为阶跃温度。

-

系统采用模块化设计,软件由主程序,4个子程序构成,即ADC采集程序、PWM波产生程序、定时器程序、PID控制程序,主程序流程图如图 3所示。PID控制程序,输入参量为设定温度值与当前温度值,输出参量为PWM波占空比(即PWM波脉宽时间)。定时器程序与PWM波周期时长相等,用于执行完单次PWM波后,读取ADC采集的电压值执行单次PID控制程序,给执行部件下达下一次所需要执行的占空比指令。

-

高速红外辐射测温模块静态标定实验选用SR20-32型中温黑体炉作为标准温度源。根据被校K型铠装热电偶尺寸,选择黑体炉辐射输出孔径,将中温黑体炉的辐射输出端放置在椭球面放射镜的一个焦点处,另外一个焦点放置高速红外辐射测温模块,如图 4所示。

为避免高速红外辐射测温模块在静标过程中长时间受到较强的热辐射导致其内部敏感元件损坏,在高速红外辐射测温模块光学窗口前添加了机械快门,在需要采集温度辐射时打开快门。该中温黑体炉的温度范围为573.15K~1273.5K,选择中温黑体炉设置从583.15K开始产生辐射,每增加10K打开一次快门,采集3次数据,取平均值。

-

根据高速红外辐射测温模块测得的数据,拟合处理后得到高速红外辐射测温模块的输出电压平均值与温度关系曲线, 如图 5所示。

拟合曲线方程如下:

式中, y代表高速红外辐射测温模块的输出电压,x代表黑体炉的温度。相关系数R2=0.99963。

-

根据斯忒藩-玻尔兹曼定律,又称为4次方定律,指出黑体辐射力与热力学温度的关系,如下式所示:

式中,Eb为黑体辐射力,单位为W/m2; σ为黑体辐射常数,单位为W/(m2·K4)。

根据光电红外探测器基本特性,整理得到:

式中, Ud为红外探测器输出电压,P为探测器接收到的功率,Rv为探测器电压响应率,η为反射镜聚焦效率,P1为黑体炉发出的功率,ε为发射率,本文中黑体炉为0.99±0.01,r为中温黑体炉的输出孔径。

根据(12)式可得红外探测器输出电压与温度不是线性的关系,而是成4次方的关系,基本吻合拟合曲线公式。

-

将已静态标定后的高速红外辐射测温模块与被校热电偶分别放置在椭球面反射镜的两处焦点处,若PWM波周期为250ms,采用信号发生器给激光器驱动电源输入单次不同占空比的方波,即输入单次不同的脉冲宽度,用高速红外辐射测温模块采集数据,实验框图如图 6所示。

-

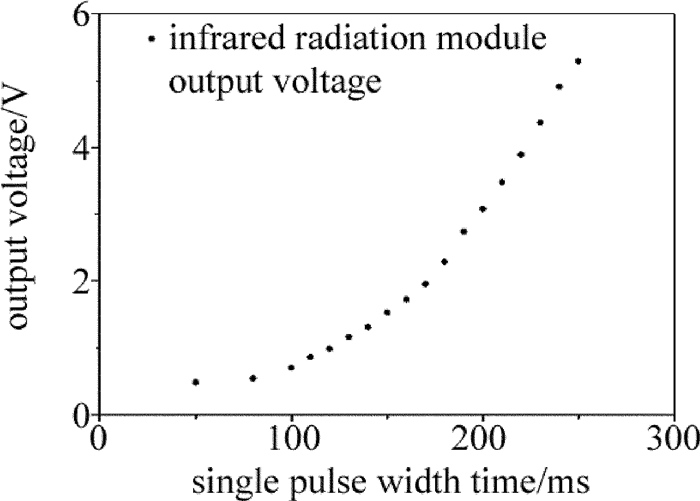

将高速红外辐射测温模块测得的输出电压与单次脉宽时间进行曲线拟合得到图 7。

将高速红外辐射测温模块电压值带入(7)式求解得到被校热电偶表面温度,拟合被校热电偶温度与脉宽时间,得到图 8。拟合公式如下式所示:

式中,y代表热电偶表面温度,x代表单次脉宽时间。相关系数R2=0.99924。

-

经过数据曲线拟合发现,单次脉宽时间与被校热电偶表面温度成3次方关系,在脉冲宽度为50ms~110ms激光段,由于热电偶表面温度较低时,热电偶测温端材料对激光的吸收率较低,所以在热电偶表面温度较低时,激光器输出较短时间激光,热电偶表面温升所产生的红外辐射十分有限, 且在传输过程中衰减,不易被红外探测器所采集到,脉宽时间的增加使得热电偶表面所产生的温度变化不明显;随着温度的上升,在激光照射的热电偶微观表面开始发生变化,对于激光的吸收率急剧上升,比起低温段,高温段由于激光吸收率的增加,虽然脉冲宽度的变化相同,但是高温段却可以实现温度的明显上升;随着温度不断增加,热电偶表面材料对于激光的吸收率趋于稳定,导致其温度变化也逐渐趋于平缓。

4.1. 高速红外辐射测温模块温度与输出电压实验

4.1.1. 实验结果

4.1.2. 数据分析

4.2. 激光激励热电偶温升实验

4.2.1. 实验结果

4.2.2. 数据分析

-

重点分析了热电偶时间常数激光测试系统中PWM调节温度过程中脉冲宽度与温度的非线性,对非线性的影响因素做了详细的分析。由于热电偶测量结点处对激光的吸收率在低温时较低,并且会随着温度上升逐步增加,导致了脉宽时间与热电偶表面温度呈3次方关系。因此,可用得出的脉宽时间-热电偶表面温度关系式实现精确控温。本系统的激光加热研究可为本系统中进一步缩短阶跃温度信号的上升沿时间的控制算法优化提供依据,在实际运用中,可用于激光加热、3-D打印的激光精确控制。

Map

Map

DownLoad:

DownLoad: