HTML

-

激光-电弧复合焊接由STEEN[1]最早提出并受到高度关注,在焊接领域中,一直是研究的热门技术之一[2-4], 继而在工业领域推广运用,并不断进行深入研究与创新,使复合焊接技术到达更高水平[5-6]。焊接过程中,保护气体是影响工艺特性的关键因素。HONG[7]等人研究发现,保护气体是通过抑制和消除光致等离子体的屏蔽效应,达到激光深熔焊的效果,提高焊接工艺稳定性。FAN[8]等人研究发现,在焊接过程中较高的温度作用下,金属熔化蒸发形成大量等离子体,以及保护气体被电离击穿,形成燃烧波等离子体,对激光产生屏蔽效应。保护气体不仅能消除等离子体屏蔽作用,还能防止在高温条件下焊接熔池被氧化或污染[9]。LI[10]等人研究复合焊接发现,有大量的电子通过电弧等离子体进入到激光等离子体,对激光逆韧致效应起到增强作用,而激光等离子体被增强和大量扩散,使其导电通道变宽。XIAO[11]等人研究发现,等离子体对临界功率密度的屏蔽作用,受到辅助气体的导热性和解离能的影响,且在聚焦状态下等离子体高度越低,越不易出现等离子体的屏蔽现象[12]。现有研究中对于保护气体控制的研究相对有限。本文中重点研究了保护气体的气流量对高强钢激光-电弧复合焊接焊缝形貌的影响,并讨论了保护气体流量对熔滴过渡动态行为的影响,以及采用FLUENT软件对气流量对焊缝形貌影响的机制进行仿真模拟。

-

试验材料采用5mm厚的高强钢样板,进行平板堆焊,其主要化学成分见表 1。焊丝直径Φ =1.2mm。

element C Si Mn P Cu Ni Mo mass fraction 0.0004~0.0008 ≤0.0035 0.015~0.018 ≤0.0002 ≤0.005 ≤0.005 ≤0.0035 Table 1. Main chemical composition of high strength steel

-

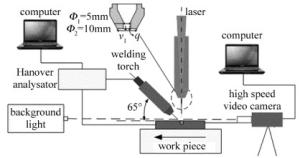

设备采用Rofin公司的CO2激光器和Panasonic YD-350AG2HGE型焊机进行旁轴复合。利用CMOS-CR5000×2型高速相机观测熔滴形态的变化,并采集熔滴区图像,其采样频率为4000frame/s。依据所采集到的熔滴图像,分析气流量对熔滴形态的影响。其复合焊接示意图如图 1所示。图中, q是保护气体流量,v1是保护气体流速,Φ1和Φ2分别是喷嘴的内外径。

试验中采用电弧在前、激光在后的焊接模式,激光束离焦量Δf =-1mm,热源间距DLA=2mm,焊枪倾角α =65°。保护气体为不同流量的He(体积分数为0.35)+Ar(体积分数为0.65)。气体流量的主要工艺参量见表 2。

sample laser power P/kW welding current I/A arc voltage U/V welding speed v/(m·min-1) protective gas flow q/(L·min-1) 1 3 180 26 1.2 15 2 3 180 26 1.2 20 3 3 180 26 1.2 25 4 3 180 26 1.2 30 5 3 180 26 1.2 35 Table 2. Main process parameters

1.1. 试验材料

1.2. 试验设备及方法

-

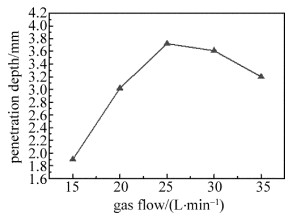

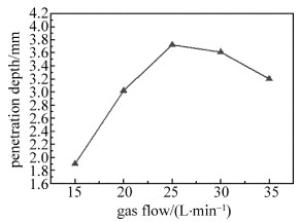

图 2为焊接熔深随气体流量变化的曲线图。从图中可以看出,气体流量越大,焊缝熔深呈先增大后减小的趋势。当气体流量达到25L/min时,焊缝熔深最大。

当保护气体流量过小时,不能对熔池形成有效保护,由于等离子体吸收部分激光能量,导致焊缝熔深较小。当保护气体流量达到25L/min时,熔深最大。在气流量作用下,等离子体对激光屏蔽作用得到有效抑制,使焊件吸收大量激光能量。保护气体流量过大时,气体流动状态由层流转变为紊流,且电弧挺度较小,对等离子体的抑制和消除作用减弱,从而导致焊缝熔深减小[7]。

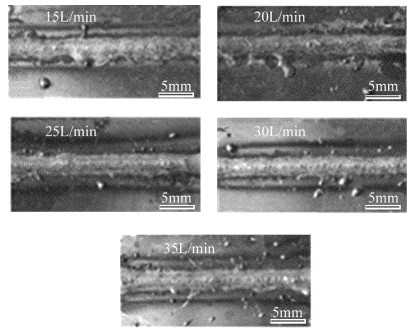

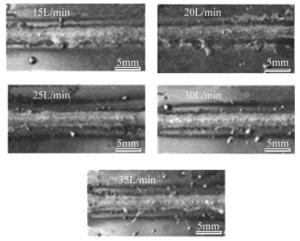

图 3为不同气体流量下,焊缝的表面形貌。从图中可以看出,随气体流量的增加,焊缝的表面铺展性逐渐变好。当气体流量为25L/min时,焊缝较平整且飞溅较少;当气体流量高于25L/min时,焊缝表面飞溅严重。

飞溅是焊接过程中较为常见的一种缺陷。随着气体流量的增大,导致等离子体对熔滴端部的机械冲击力增大,且斑点压力增大,造成颗粒飞溅。

-

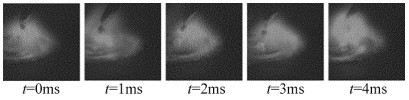

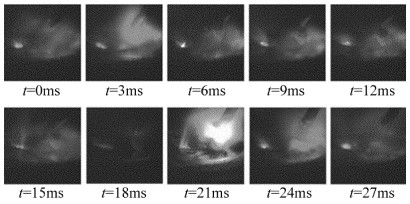

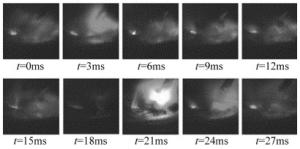

图 4为气体流量15L/min时熔滴的瞬态形貌。此时熔滴过渡方式为颗粒过渡。从图中可以看出,熔滴的周期较短,且熔滴尺寸较小。主要是由于金属表面熔化形成熔池时,激光作用产生匙孔时的蒸气反作用力阻碍熔滴的过渡。因保护气体流量较小,对等离子体对激光的屏蔽作用起不到较好的抑制与消除作用,导致阻碍熔滴过渡的蒸气反作用力不稳定,而产生颗粒过渡,使焊缝表面成形不良。

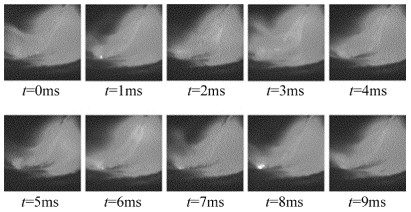

图 5是气体流量为25L/min时的熔滴瞬态形貌。从图中可以看出,熔滴过渡方式为射流过渡,且熔滴的尺寸增大,熔滴过渡的周期变长。

射流过渡是复合焊接中理想的过渡模式,是因为射流过渡时能够获得表面平整的焊缝,且熔深大。保护气体流量能有效地减轻等离子体对激光的抑制作用,有大量的能量到达金属表面;因较大气流量的作用,使熔滴受到离子流的冲击力,则熔滴对熔池产生较大的冲击力,更多能量到达熔池底部[13]。

图 6是气体流量为35L/min时熔滴过渡的瞬态形貌。从图中可以看出,熔滴过渡的方式为短路过渡,且熔滴过渡的周期变长,当熔滴与熔池接触时,会突然变暗后变亮。

由于气体流量较大,在熔池上方会产生较大的等离子体流力,与表面张力共同阻碍熔滴脱落,使熔滴尺寸增大到焊丝直径的1.5倍左右。熔滴端部与熔池接触,且在电磁收缩力的作用下实现过渡,过渡过程不稳定,工件表面出现严重的飞溅[14]。主要是因为继续增大气体流量,熔滴过渡模式为明显的短路过渡,聚集成大熔滴脱离焊丝瞬间极易爆炸形成飞溅,使焊接工艺的稳定性下降[15]。

-

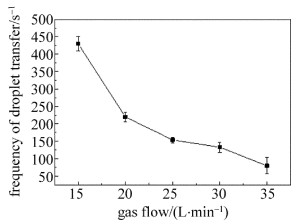

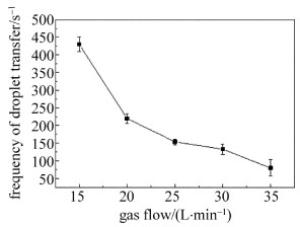

图 7为气体流量对熔滴过渡频率的影响。从图中可以看出,激光电弧复合焊接的熔滴过渡频率随着保护气体流量的增大而减小。当气体流量较低时,熔滴的过渡频率不稳定;气体流量为25L/min时,熔滴为射流过渡,且过渡频率较为稳定。

保护气体流量的增加改变了熔滴的受力情况以及过渡模式,从而引起熔滴长大周期发生变化,直接导致熔滴过渡特性发生变化。

熔滴过渡过程中,在气体流量的作用下,熔滴受阻碍其过渡的反作用力(离子流冲击力和金属蒸气的反冲力)影响,气体流量越大,反作用力越大,斑点力越大[16]。同时在熔滴内产生阻碍其过渡的电磁收缩力[17]。根据静力平衡理论,当保护气体流量较小时,阻碍熔滴过渡的力小,熔滴脱落时所需要的重力就会相应减小,熔滴脱落的尺寸较小,熔滴过渡频率大;反之,随保护气体流量增大,阻碍熔滴分离的反作用力就越大,熔滴在脱落时的尺寸增大,熔滴过渡频率减小[18]。

2.1. 气体流量对焊缝形貌的影响

2.2. 气体流量对熔滴形态的影响

2.3. 气体流量对熔滴过渡频率的影响

-

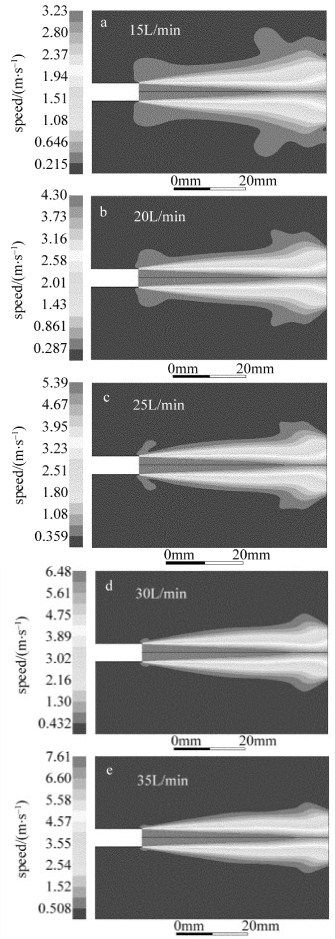

根据流体力学原理,采用FLUENT软件对气体流量进行模拟仿真,其主要目的是通过模拟结果确定保护气体的作用范围、对等离子体的作用以及对熔滴的受力情况。

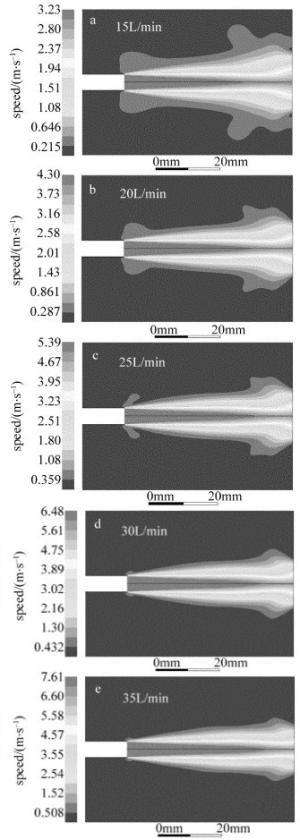

图 8是不同气体流量作用下的模拟云图。从图 8可以看出, 随着气体流量的改变,气体到达工件表面的速度分布就会不同,且气体流量越大,气体喷射到工件表面的速度越大。从云图分布可以看出,保护气体到达焊缝中心的速度最大,越远离焊缝中心,其速度越小,且随气体流量的增大,保护气体作用的范围减小。保护气体流量是通过影响等离子体进而影响熔滴过渡特性以及焊缝的形貌。

图 8a中气体流量为15L/min。可以看出,保护气体喷射到工件表面时,作用的范围较大,形成良好的保护焊道,且给焊道提供优良的冷却条件,有利于焊缝成形。但气体流速较低,气体的流层挺度较低,导致保护气体对激光等离子体的抑制效应降低,使较少的激光能量达到焊接工件表面,从而导致母材金属蒸发不完全,最终导致熔深较小。

图 8c中气体流量为25L/min。此时保护气体流速最高达到5.31m/s,有效地抑制了激光等离子体的膨胀,增大了对熔池的吹力,促进熔池的流动,使焊接熔深达到最大。根据静力平衡理论,熔滴受重力、电磁力、等离子体流拉力以及表面张力的影响。当焊缝中心处的保护气体流速达到5.31m/s时,等离子体流拉力较大,熔滴过渡的特性为射流过渡,会使焊接较稳定,焊缝铺展性较好。

图 8e是气体流量为35L/min时保护气体流速的模拟云图。图中保护气体流速最大为7.434m/s,且保护气体在工件表面的保护范围较小,导致焊道冷却效果较差。由于保护气体的流速过大,使等离子体流拉力较大,但金属蒸汽形成的气体射流对熔滴的反作用力更大,使熔滴受力不平衡,由于熔滴过渡方式转变为短路过渡,熔滴过渡不稳定,导致复合焊接不稳定[19]。同时因为增大了熔滴过渡周期,熔滴的尺寸也增大,使熔滴过渡频率降低。

-

(1) 随着保护气体流量的增大,焊缝熔深先增大后减小。当保护气体流量为25L/min时,焊接熔深达到最大,焊缝成形较好,飞溅较少。

(2) 不同的气体流量,熔滴过渡的特征呈现不同的形式。当气体流量为15L/min时,熔滴过渡方式为颗粒过渡;当气体流量为25L/min时,为射流过渡;当气体流量高于30L/min时,为短路过渡。

(3) 随着气体流量的增大,熔滴过渡频率会降低。气体流量为25L/min时,熔滴的过渡频率较为稳定; 气体流量小于20L/min时,过渡频率下降的趋势较剧烈。

(4) 数值模拟气体流量,气体流量越大,保护气体流速越大,对熔池的吹力越大,会促进熔池的流动。当气体流量为25L/min时,保护气体会有效抑制等离子体。

Map

Map

DownLoad:

DownLoad: