HTML

-

Al2O3陶瓷是目前世界上应用最为广泛的陶瓷材料之一,在生物、电子等领域已成为不可或缺的材料[1]。传统的机械加工、电火花加工和超声波加工Al2O3陶瓷等方法,都存在无法钻微小孔、钻孔效率低和工件磨损严重等问题[2]。自从激光器诞生以来,激光的种类和利用激光进行材料加工已经获得蓬勃发展[3]。激光应用领域逐步扩大到各种金属和非金属板材的加工,解决了许多传统切削加工无法解决的问题[4]。微孔激光加工技术是激光加工技术的一个新兴和重要领域,随着科技和社会生产的迅速发展,一方面给激光钻孔提出了各种各样更高的要求;另一方面技术的进步和先进设备的出现也使得高效率、高质量钻孔成为可能[5]。目前微孔加工领域主要存在的问题是:在加工微孔过程中,不仅要使材料易于加工,还应努力提高微孔的钻孔质量,减少微孔锥度和消除重铸层、微裂纹等问题。

目前,国内外学者相继采用不活泼气体辅助激光加工[6-7]、激光钻孔样品化学再腐蚀[8-9]和超短脉冲激光加工[10-11]等手段来去除重铸层,但效果均不完美,未能完全消除重铸层,主要原因在于上述手段不能完全避免热效应的存在,依然有熔融物重新附着于原材料表面。而水辅助激光钻孔由于激光诱导液体空化作用、水的冷却作用和水的流动作用能够在一定程度上降低光热效应和抑制去蚀材料的二次黏附。曾经有学者[12-13]在纳秒、毫秒等激光器下利用水辅助激光切割陶瓷,虽未能完全消除热效应和重铸层,但加工质量明显优于空气中激光加工。

本文中在前人的基础上采用水辅助超短脉冲激光对Al2O3陶瓷进行钻微孔研究,对比水和空气介质中钻孔的直径、微孔锥度和重铸层厚度等质量效果,研究水辅助激光钻孔的影响机理。

-

实验中所用Al2O3陶瓷3维尺寸为28mm×21mm×625μm,Al2O3的质量分数为0.96,能带宽度约为9.1eV,常用物理性能见表 1。

properties reference value melting point 2072℃ boiling point 2977℃ density 3.72g/cm3 heat capacity 880J/(kg·K) elasticity modulus 74GPa shear modulus 300GPa coefficient of thermal expansion 8.2×10-6K-1 Table 1. Physical parameters of soda-lime glass

-

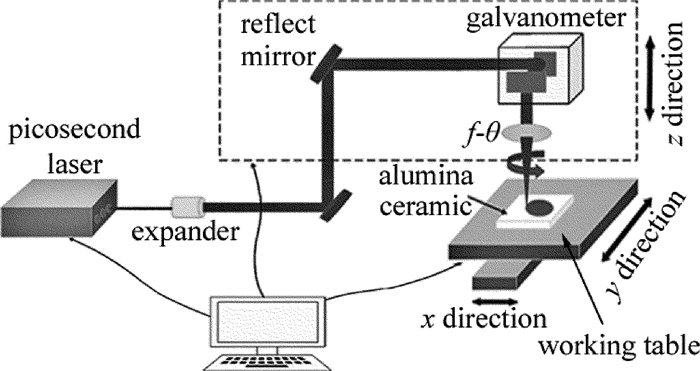

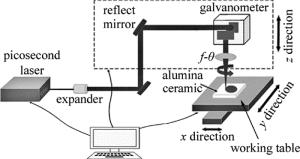

实验中采用的激光加工设备为多功能皮秒激光微加工系统,主要由多波段全固态皮秒激光器、微加工光路系统、精密机械系统、定位系统和计算机控制系统构成。激光器是德国Edgewave公司生产的Nd:YVO4皮秒激光器,输出波长1064nm,光束质量因子M2≤1.3。激光输出平均功率为0W~80W,脉冲宽度10ps,脉冲重复频率为200kHz~20MHz,出口光斑直径3.0mm,经透镜聚焦后的焦点光斑直径约为20.0μm。使用振镜扫描配合加工平台X-Y-Z 3维运动方式,可实现对70mm×70mm范围内任意复杂图形快速加工,最高扫描速度为9600mm/s。加工系统示意图如图 1所示。

-

实验研究激光主要参量(单脉冲能量和扫描次数)对微孔直径、锥度和重铸层厚度影响规律以及皮秒激光在不同介质中与Al2O3陶瓷的作用机理。钻微孔目标直径D=200μm,钻孔方式采取单层多次同心圆填充旋切钻孔法,填充间距固定为10μm。激光聚焦平面位于Al2O3陶瓷表面上,焦点处有效光斑中心位于同心圆上。在空气介质中加工只需将Al2O3陶瓷样品放在加工平台上直接按设定参量进行加工,而水辅助激光钻孔则需要支撑和固定装置将Al2O3陶瓷固定于水下。

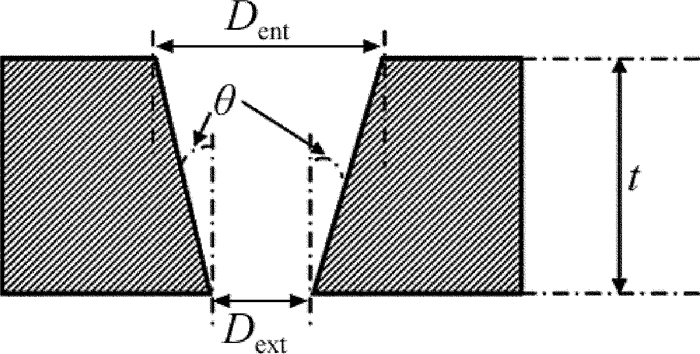

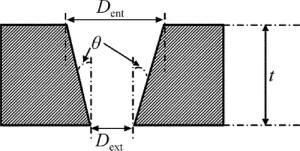

微孔锥度是陶瓷微孔在材料厚度方向上的倾角θ,如图 2所示。锥度T计算公式如下:

式中,θ为倾角,单位是°;Dent和Dext分别为正、反面孔径,单位均是μm;t为Al2O3陶瓷厚度,单位是μm。

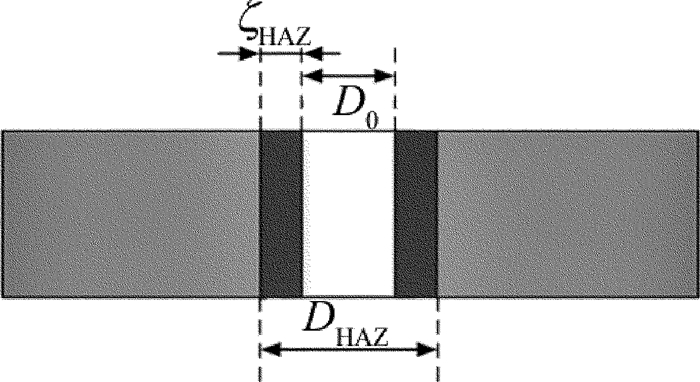

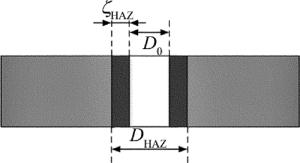

重铸层主要由于材料熔化重新冷却固化在内壁上,如图 3所示。计算公式如下:

式中,ζHAZ是重铸层厚度,单位是μm;DHAZ是包括重铸层在内微孔直径,单位是μm;D0是材料完全去除时微孔直径,单位是μm。

1.1. 实验材料

1.2. 实验设备

1.3. 研究内容

-

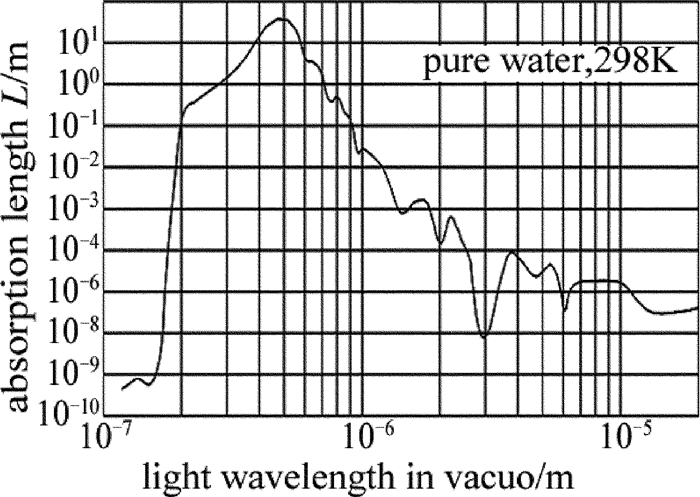

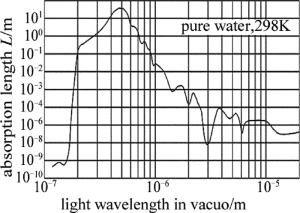

激光束在水中传输时,水对激光的吸收作用与散射作用同时存在。激光束能量的衰减主要是纯净水与水中杂质对激光的吸收引起,对激光束的扩散影响不大。激光在纯净水中的传输特性如图 4所示。在水辅助激光钻孔过程中,水能够吸收一部分激光能量并降低加工效率。水吸收的激光能量可以由Beer-Lambert定律[14]计算得到,如下式所示:

式中,I0(λ)是入射前激光初始辐照度;Ix(λ)是在液体中传输路程为x后的激光辐照度;L是激光在水中的吸收长度,即激光被完全吸收穿过的溶液长度。

因此可以很容易看出, 波长λ=1064nm激光对应纯净水吸收长度L≈15mm。水深h=1mm时,吸收率δ≈h/L=6.7%;水深h=2mm时, 吸收率δ≈13.3%。而散射作用主要使激光束扩散、光斑变大,对激光束能量衰减影响较弱。深度为x处的激光光斑大小S计算公式[15]如下:

式中,ρ〈σs〉是水质参量,S0是初始光斑直径,σs是平均散射截面。

-

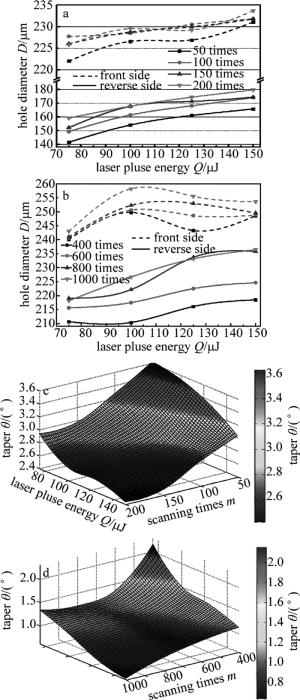

本文中对空气和水不同介质中激光加工参量对陶瓷微孔的锥度和密封性影响规律进行了研究,主要的研究参量是激光单脉冲能量和扫描次数。实验中设定的参量变化范围如下:激光单脉冲能量为75.0μJ~150.0μJ;空气介质中的扫描次数为50次~200次;水介质中的扫描次数为400次~1000次。脉冲重复频率恒定为200kHz;扫描速率恒定为200mm/s;水辅助时陶瓷表面离水面深度为2mm。微孔直径和锥度的数据曲线如图 5所示。

在上述钻孔激光参量条件下,微孔直径随着单脉冲能量和扫描次数的增加呈现增加趋势,锥度随着单脉冲能量和扫描次数的增加呈现下降趋势。水辅助激光加工孔径增大主要是水对激光散射作用致使激光光斑增加。已知空气中有效光斑直径d=20μm,中心位于最外圈同心圆上,设定钻孔直径Dent=200μm,空气介质中激光钻孔正面孔径在Dent,1≈220μm,水辅助激光钻孔正面孔径稳定在Dent,2≈250μm,则散射作用引起孔径增大,Δ2=Dent,2-(Dent+d)=30μm,从而计算出水辅助激光钻孔在最后阶段有效光斑直径d′=d+$\frac{{{\Delta _2}}}{2} $=35μm,根据(4)式推算出水介质中钻孔最后阶段对应的水质参量ρ〈σs〉=0.28。空气介质中激光钻孔锥度分布范围为2.6°~3.6°,如图 5c所示,在单脉冲能量为150μJ和扫描次数为200次时能获得最低锥度(2.6°)。水介质中激光钻孔锥度分布范围为0.8°~2.0°,如图 5d所示,在单脉冲能量为150μJ和扫描次数为1000次时能获得最低锥度(0.8°)。

图 6中是皮秒激光分别在空气和水介质中对陶瓷钻微孔样品的光学显微镜剖面微观形貌图。图 6a~图 6d是在空气介质中激光单脉冲能量范围在75μJ~150μJ,增量为25μJ,扫描次数50次所获得的微孔,在微孔顶部有明显的热影响区,存在较大的锥度。图 6e~图 6h是水介质中激光单脉冲能量范围在75μJ~150μJ,增量为25μJ,扫描次数600次所获得的微孔。随着单脉冲能量的增加,水辅助钻孔的孔型逐渐向圆柱状转变,锥度明显小于空气中激光钻孔,并且空气中激光钻孔在微孔顶部有明显的热影响区,水辅助激光钻孔则没出现热影响区,内壁颜色与陶瓷原表面相同。

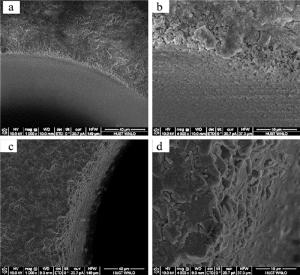

空气介质中皮秒激光钻孔内壁重铸层厚度变化范围为3.5μm~8.0μm,重铸层厚度随着单脉冲能量和扫描次数增加而增加,在单脉冲能量为75μJ和扫描次数为50次时重铸层厚度为3.5μm。图 7是扫描电镜分别对空气和水介质中的激光钻孔样品进行微观形貌观察。所选用的激光参量如下:激光单脉冲能量为100μJ,空气介质中扫描次数为50次,水介质中扫描次数为600次。在空气介质中激光钻的微孔可以明显地发现, 孔内壁表面附着一层细小颗粒,即为在激光钻孔过程中熔融物重新凝结而形成的重铸层,颗粒细小,与陶瓷原表面相比重铸层有泛白倾向,但无微裂纹产生,如图 7a和图 7b所示。

水介质中皮秒激光钻孔在低单脉冲能量和低扫描次数下,微孔表面无重铸层、微裂纹和发黑变质区,孔壁清洁度高、无激光烧蚀痕迹,如图 7c和图 7d所示。在水介质中进行激光钻孔加工时,由于水的比热容远大于陶瓷材料,因此水的冷却作用使得陶瓷材料表面温度很难达到其熔点,陶瓷难以发生相变,因此无发黑变质和微裂纹现象。水辅助激光钻孔参量与重铸层厚度关系为:当单脉冲能量Q≤100μJ时,在扫描次数为400次~1000次范围内无重铸层产生;当单脉冲能量Q=125μJ时,在扫描次数为,在扫描次数为800次~1000次范围内出现重铸层,最大厚度为0.82μm;当单脉冲能量Q=150μJ,在扫描次数为600次~1000次范围内出现重铸层,最大厚度为1.15μm。

水辅助激光钻孔过程中,主要存在水的冷却作用、空泡作用和运输作用。水的高比热容能够传递和吸收激光能量,能够初步降低热影响区和减少重铸层。空泡作用是皮秒激光加工时由于超高的峰值功率密度,超过物质击穿阈值产生液体空化,形成大量空泡,溃灭时产生的冲击波使熔融物能与基体脱离。同时水的存在会阻碍熔融物无法二次黏附在基体表面,同时微孔内外压强差,使得水不断流动将残渣送出陶瓷孔外,从而降低微孔锥度和去除重铸层。

-

本文中采用水辅助脉宽10ps的激光加工系统和同心圆填充旋切钻孔技术,实现了Al2O3陶瓷无重铸层激光钻孔,并对微孔的孔径、锥度、重铸层厚度和微观形貌观察。

(1) 水辅助激光钻孔时,孔径、锥度和重铸层厚度随激光参量的变化规律与空气中直接钻孔的变化趋势基本一致,但水辅助钻孔的孔径比空气中钻孔大,锥度和重铸层厚度比空气中钻孔小,在低单脉冲能量和低扫描速度下,能够实现完全无重铸层。

(2) 水辅助激光钻孔时,孔径的扩大主要是由于水对激光束的散射作用引起的。本文中激光光斑直径因水中悬浮物扩大约为35μm,增大率约为75%,对应的水质参量约为0.28。

(3) 水辅助激光钻孔在合适的参量能够实现无重铸层,小锥度高质量钻孔,具体参量是:脉冲重复频率200kHz,单脉冲能量125μJ和扫描次数600次,能够实现锥度为1.04°无重铸层激光钻孔。

(4) 水辅助激光钻孔时,由于水的冷却作用使得陶瓷表面温度难以达到其熔点,表面基本看不到激光钻孔痕迹。皮秒激光钻孔过程中由于具有高功率密度激光,会引起液体空化现象,空泡溃灭对孔壁产生强冲击作用,使得重铸层脱离基体,并且通过水的流动作用将悬浮物运出微孔内部,从而彻底实现无重铸层钻孔。

Map

Map

DownLoad:

DownLoad: