HTML

-

铝合金因其具有较高的比强度、良好的工艺成形性、断裂韧性及优良的耐蚀性能,适应传统产业改造升级和现代高新科技发展的需要,已经被广泛应用于机械制造、运输机械、动力机械及航空工业的焊接结构中[1]。传统的铝合金焊接方法主要有钨极氩弧焊(tungsten inert gas welding,TIG)、熔化极惰性气体保护焊(metal inert-gas welding,MIG)[2]等。传统的焊接方法不仅熔透能力差、焊接效率低,并且焊接变形大、焊接质量较低[3]。激光焊作为最有前景的焊接方法之一,具有焊速高、能量密度高、线输入低等诸多优点,但是在铝合金的焊接过程中也存在一些不易克服的问题,其中最常见的问题是气孔[4]。气孔会严重破坏焊缝金属的致密性、削弱焊缝的有效截面积,极大地降低焊缝的力学性能和耐腐蚀性能[5]。

近年来,激光行业的国内外学者及相关从业人员开展了大量的研究。清华大学的ZHAO等人研究了摆动光束对低碳钢激光焊接气孔的影响, 发现光束摆动激光焊接可以减少和消除气孔;摆动频率越大,摆动幅度越大,对熔池的搅拌越大,越有利于气泡的逸出,气孔越少[6]。清华大学的BAO等人则进行了光束摆动时对超细晶粒钢的焊缝组织性能影响的研究,发现随着摆动频率的增加,冲击吸收能量和拉伸强度显著增加;在最优摆幅和频率下,摆动焊的焊缝强度比无摆动的焊缝相强度有提高,而韧性提高了8.74%[7]。激光摆动焊接不仅在对间隙、不等厚板的适应性上有着显著优势[8],而且对微观组织的改善、气孔及裂纹的出现也有着明显的抑制能力[9]。由于摆动振幅和摆动频率的增大,光束摆动引起的熔池搅拌力明显提升,极大地利于气泡的逸出[10],气孔率显著下降,并且随着摆动频率的增加,冲击吸收能量和拉伸强度亦显著增加。研究表明,激光摆动焊接还可以抑制铝合金的凝固裂纹,从而提高焊缝性能。

不仅如此,国内外学者及相关从业人员还尝试了各种焊接手段,如激光填丝焊、激光-MIG复合焊、激光-TIG复合焊等等,但都只使得铝合金焊接质量在非常有限的程度上得到了改善,公开报道的文献中尚未见到基本消除气孔这一缺陷的铝合金焊缝。因此,激光摆动焊接法对解决上述问题显示出了良好的前景[11]。

-

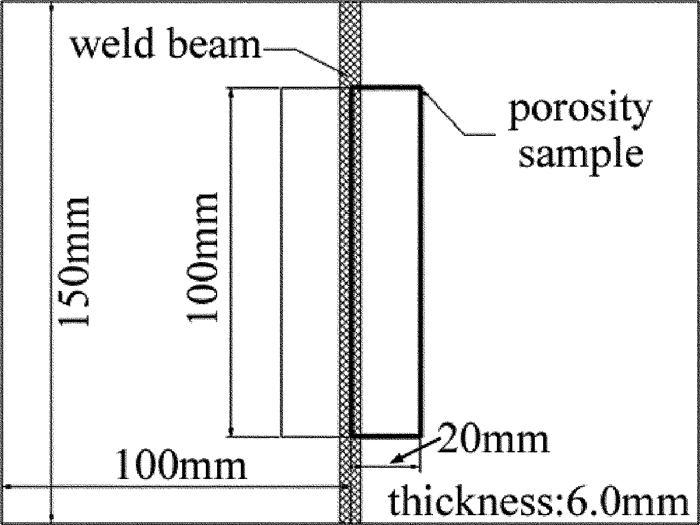

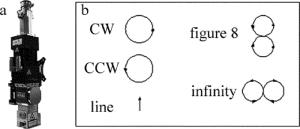

实验中以6.0mm厚5183铝合金试板为研究对象,试板尺寸为100.0mm×150.0mm×6.0mm,采用WDW-200E微机控制电子式万能试验机测得其抗拉强度为307MPa,化学成分含量如表 1所示。实验中对材料进行化学除油、机械去氧化皮处理,并置于干燥箱中干燥。

material Si Fe Cu Mn Mg Cr Zn Ti Al 5183 0.0040 0.0040 0.0010 0.0040~0.0100 0.0080~0.0120 0.0005~0.0025 0.0025 0.0015 balance Table 1. Chemical composition (mass fraction) of 5183 aluminum alloy

-

传统的激光摆动焊接,准直光束通过单轴振镜摆动,经过聚焦镜聚焦的光斑又与焊接头配合相对于工件移动,形成具有一定振幅、频率和偏移量的焊缝;而2轴振镜系统的摆动焊接则是通过控制系统形成一条摆动焊缝,需要较高的成本[12]。这些都阻碍了激光摆动焊接法的应用。

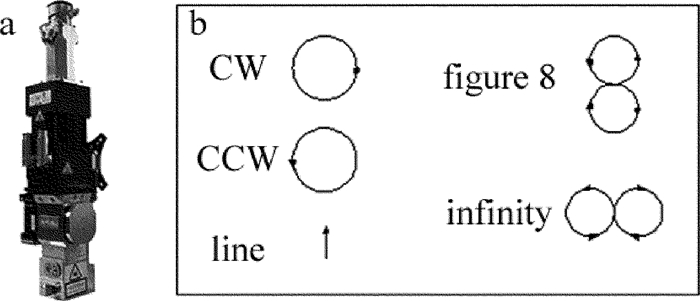

相对于传统摆动焊接模式,本文中采用的双楔形镜旋转D50激光摆动焊接(以下简称激光摆动焊接,如图 1所示),其焦点处光斑直径为0.4mm,通过安装于准直镜和聚焦镜之间的摆动模块,使聚焦光斑在焊接头移动的情况下产生螺旋线式的焊缝[13]。当聚焦焦距相同时,扭转角度越大,则摆动幅度越大;扭转角度相同时,聚焦焦距越大,则摆动幅度越大[14]。这就给激光摆动焊接的应用提供了良好的基础。激光摆动焊接头能提供光束平面上x, y两个方向的运动合成,以此得到5种激光摆动下的扫描模式,分别为顺时针圆(clockwise,CW)、逆时针圆(counter-clockwise,CCW)、直线、数字8及无穷大。并且,每种扫描形式下可提供的宽扫描振幅(0.0mm~3.0mm)和扫描频率(0Hz~300Hz)。

-

试验中所用激光器为IPG公司生产的型号为YLS-10000的光纤激光器,其最大输出功率为10.0kW,输出模式为TEM00,连续输出,激光波长为1070nm,采用芯径为0.2mm光纤进行传输。

焊接机器人为KUKA KR 60 HA六轴机器人,其额定负载60kg,重复精度不大于0.05mm,最大作用范围2033mm。焊接过程中通过机器人夹持焊接头来控制激光的运动轨迹。

-

实验前期,确定优化的焊接参量为:激光功率P=5000W,焊接速率vweld=1.8m/min,离焦量Δf=0mm。实验过程中采用高纯氩气(99.999%)保护,其流量为25L/min。通过依次改变激光摆动焊接参量(扫描模式、扫描频率、扫描振幅)来研究其对铝合金气孔的影响,以此来推断其对强度等性能的影响。并按所得规律选取最优工艺参量进行实验,对实验所得焊缝进行宏观微观金相分析、拉伸试验、焊缝无损检测等手段进行分析。实验中,为防光纤被反射光所损伤,焊接过程中激光束偏移试板的法向约5°。

-

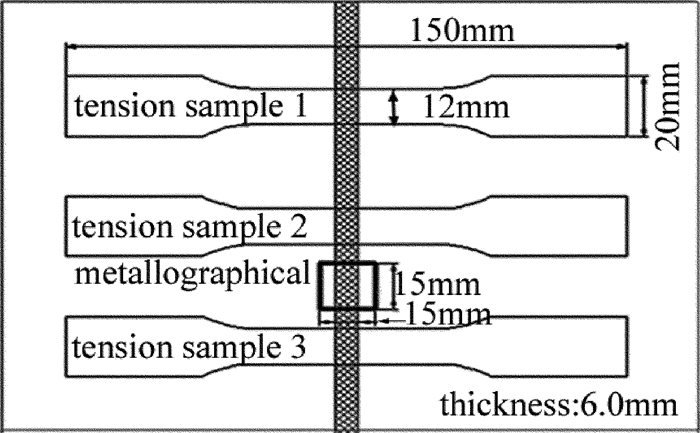

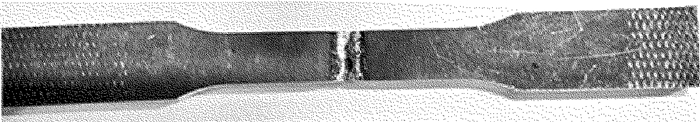

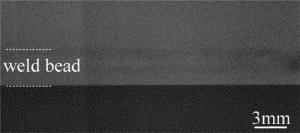

焊后按图 2所示方法取焊缝中心纵截面,观察气孔形貌和分布。取100mm等长度焊接试样沿焊缝纵向采用线切割偏向一侧切开,用水磨砂纸预磨到焊缝中心,进行抛光、腐蚀,用数码相机对焊缝纵截面取照,并对照片进行处理。采用Dino-lite Digital Microscope电子显微镜观察焊缝形貌,XJL-03金相显微镜观察焊缝组织,WDW-200E微机控制电子万能试验机对其进行力学性能测试,拉伸试样示意图如图 3所示。

定义气孔率δ为焊缝截面气孔面积Ap与截面总面积的比值Aw,即:

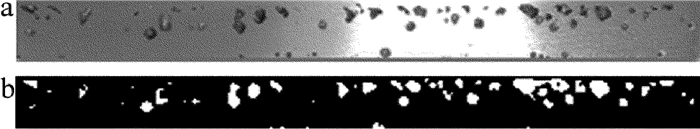

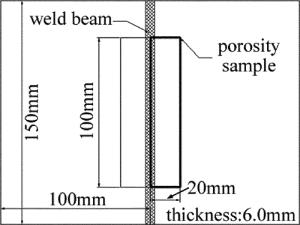

使用ImageJ软件处理自动计算焊缝截面气孔率,软件处理效果如图 4所示。实验中均用此方法来定量测量并比较焊缝气孔率。

1.1. 实验材料

1.2. 实验设备

1.2.1. 激光摆动焊接头

1.2.2. 其它设备

1.3. 实验方法

1.3.1. 实验方法

1.3.2. 检测方法

-

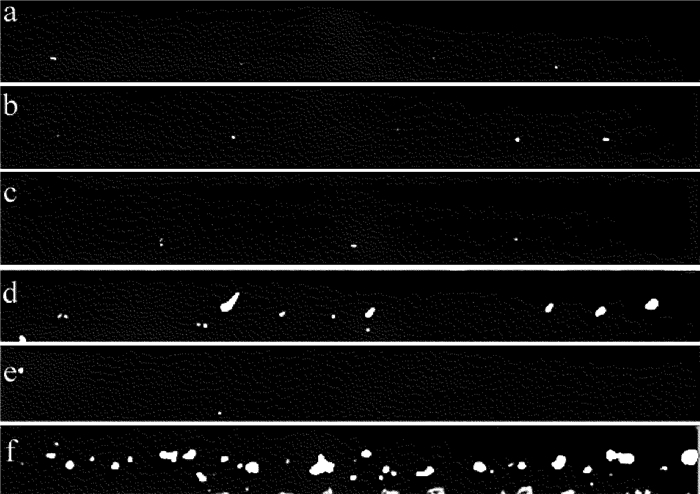

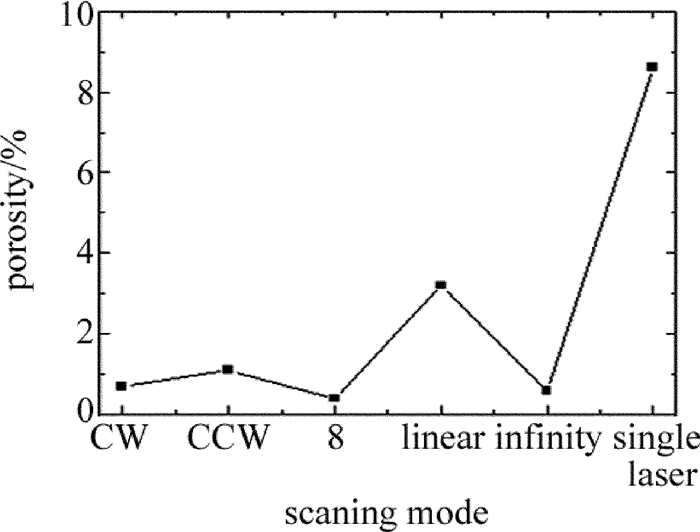

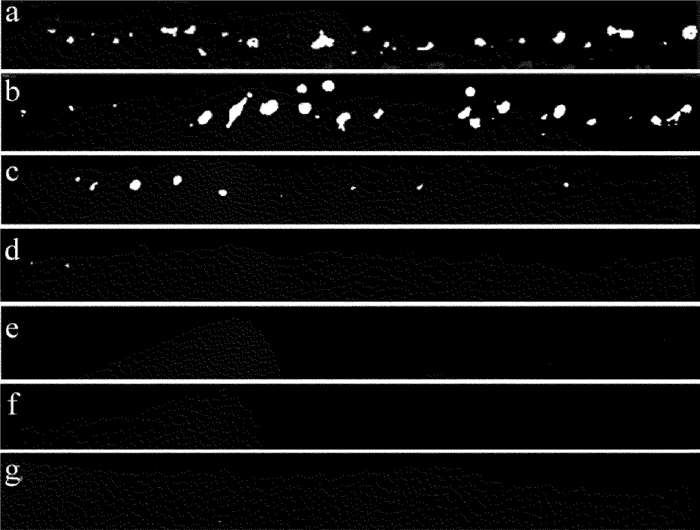

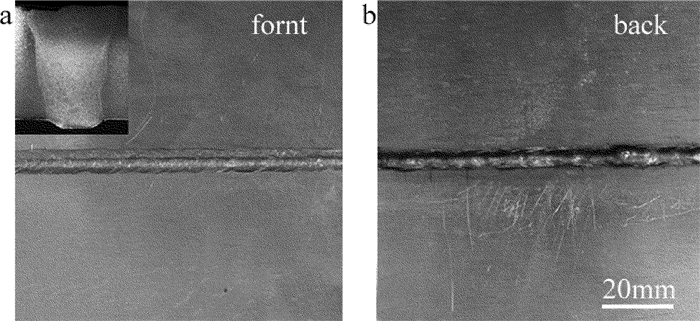

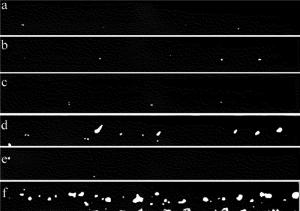

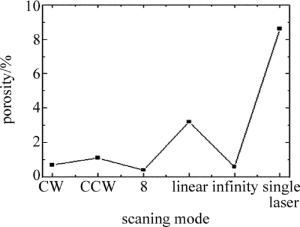

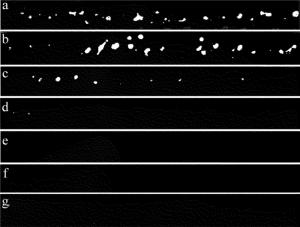

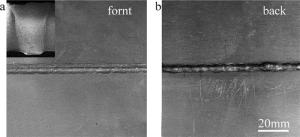

固定扫描频率300Hz、扫描振幅3.0mm,对不同扫描模式进行实验。图 5所示的是不同扫描方式下焊缝截面气孔分布图。图 6为不同扫描模式下的气孔率曲线。由此可知,单激光时所得焊缝存在相当多的气孔,其中焊缝下部多为匙孔失稳造成的工艺性气孔,上部多为氢气孔。当加入摆动之后,由于摆动的激光束对熔池不断地搅拌,使得熔池流动速率增大,增强了熔池的对流行为,有利于气泡的上浮;同时激光的摆动过程起到了焊前预热焊后缓冷的作用[15],对已处于凝固阶段的焊缝有重熔的作用,此时熔池的凝固速率降低,给予了气泡更多的上浮逸出时间;另一方面激光热源的扩展,使得熔池的面积增大,深宽比相较于传统激光焊有所减小,激光匙孔更为稳定[16]。

在激光摆动焊接的情况下,由于直线模式下由于熔池在光束摆动的带动下运动,在焊缝两侧折返时速度突变为零,此时熔池状态不稳定失稳形成气孔。因此,除了直线扫描模式下仍存在少量气孔,其它模式下均实现基本消除气孔。

-

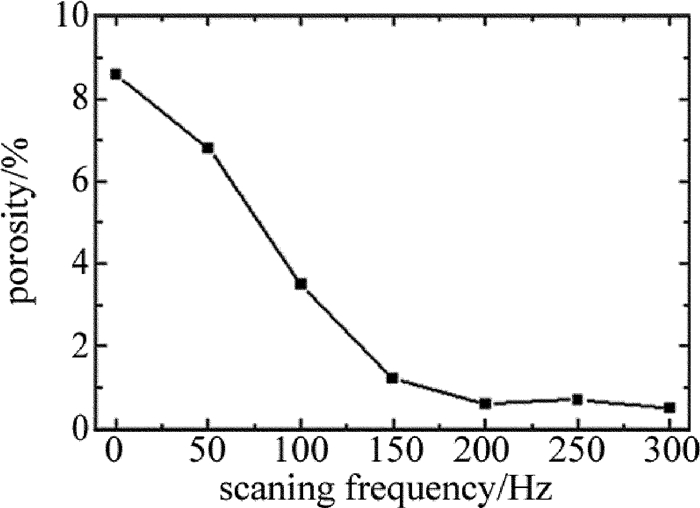

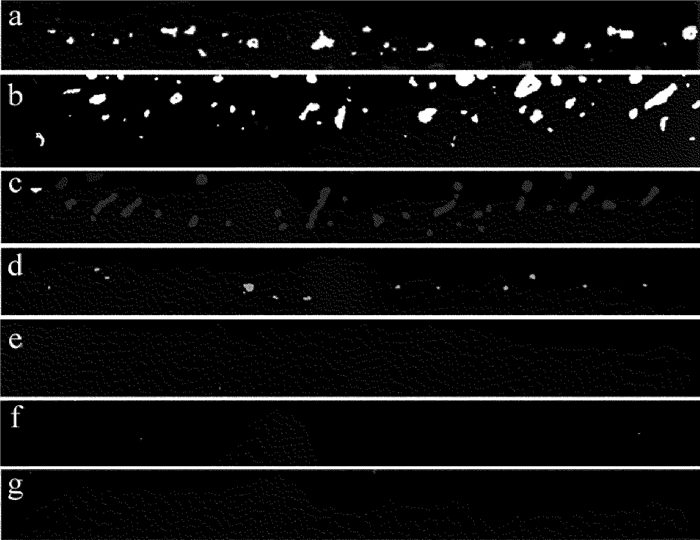

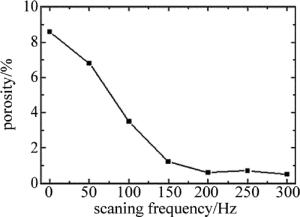

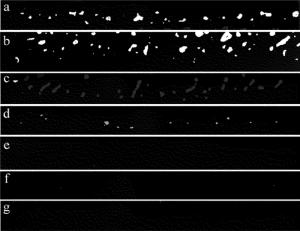

由上可知,除直线扫描模式下气孔率较高外,其余几种焊缝截面气孔均较少,并且以无穷大模式下为最少(0.5%)。因此,固定扫描模式无穷大,扫描振幅3.0mm,对不同扫描频率进行以下实验。图 7为不同扫描频率下的焊缝截面气孔形貌及气孔率。相应的气孔率曲线图如图 8所示。在高频扫描(高于150Hz)时,焊缝的深宽比不断减小,激光匙孔更加稳定,同时更有利于气泡的上浮溢出。同时扫描频率的提高意味着光束在垂直于焊缝方向速率越快,如该试验中频率为300Hz时,在垂直于焊缝方向光束的运动速率为600mm/s,而频率为50Hz时, 速率仅为100mm/s,光束在沿着焊缝方向速率均为30mm/s,垂直方向速率越高,光斑在水平与垂直方向的重叠率都得到提高,使得光束对熔池的搅拌以及熔池的对流作用增强,气孔产生倾向也更小[17]。

可知,焊缝气孔数量随着激光扫描频率的增大显著减小,当扫描频率高于200Hz时,获得了基本无明显可见气孔的优良焊缝。

-

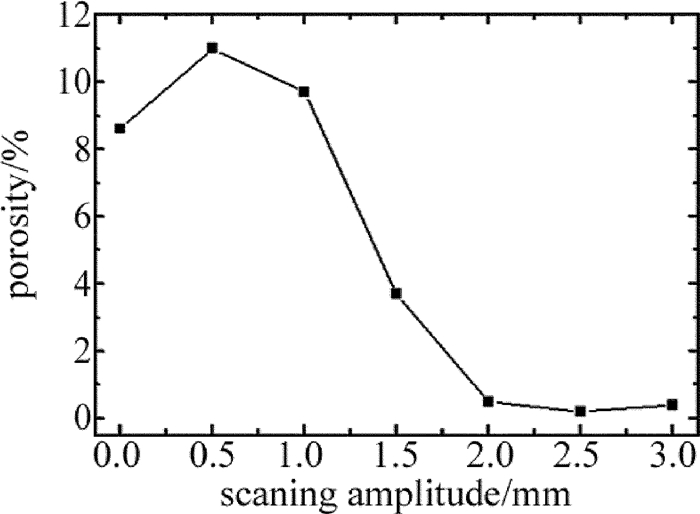

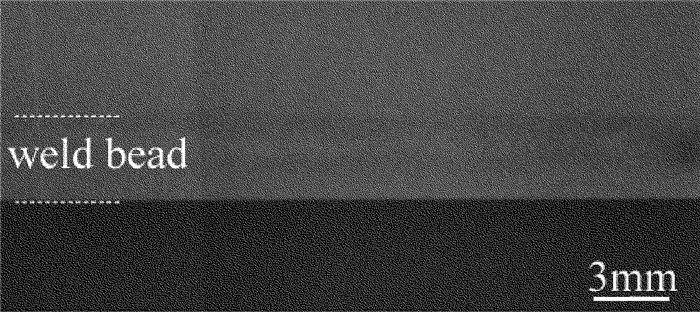

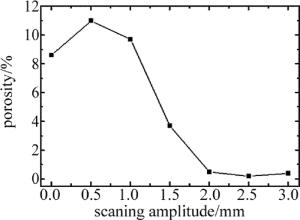

固定扫描模式为无穷大、扫描频率300Hz,对不同扫描振幅进行以下实验。图 9为不同扫描频率下的焊缝截面形貌及对应气孔率。相应的气孔率曲线图如图 10所示。可知,焊缝气孔数量随着激光扫描振幅的增大显著减小,当扫描振幅大于2.0mm时候,获得了无明显可见气孔的优良焊缝。

当扫描振幅大于2.0mm时,焊缝的深宽比不断减小,激光匙孔更加稳定,同时更有利于气泡的上浮溢出[18]。同时较宽的振幅由于光束能量被严重削减,光束虽并未形成熔池,但大幅降低了焊缝的冷却速率,延长了焊缝凝固时间,也为气泡的溢出创造了有利的条件[19]。

2.1. 不同扫描模式对铝合金气孔的影响

2.2. 不同扫描频率对焊缝气孔率的影响

2.3. 不同扫描振幅对气孔率的影响

-

(1) 在不同扫描形式下,激光摆动焊接法能显著减少气孔产生。除在直线扫描形式下仍存在少量气孔外,其余4种(CW、CCW、数字8和无穷大)扫描形式可实现无明显气孔。

(2) 随着扫描频率和扫描振幅的提高,气孔倾向显著越小。当扫描频率大于200Hz及扫描振幅大于2.0mm时,能得到无明显气孔的优良焊缝。

(3) 6.0mm厚5183铝合金对接最优扫描工艺为扫描模式为无穷大,扫描频率300Hz,扫描振幅3.0mm,此参量下能得到内部无气孔、抗拉强度271MPa、为母材强度88%的优良对接接头。

Map

Map

DownLoad:

DownLoad: