HTML

-

热电偶由于性能稳定、经济耐用和测温范围广等优点,广泛应用于生产生活各个领域,其测量结果及精度与热电偶的动态特性密切相关。时间常数作为热电偶动态特性最重要的指标,是判断热电偶质量和使用范围的重要物理量,因此对其准确测量尤为重要[1-4]。传统的投入实验法、热风洞法具备操作方便、可重复度高的优点,但是也存在机械结构速度慢,会产生人为的不可避免误差等一系列缺点[5-6]。激光是一种特殊的可控电磁波,TASHIRO等学者首次将其用于传感器的动态校准中,其后WANG,YANG等人不断完善测试理论,为热电偶时间常数测量提供了一种新的测试方法[8-9]。激光具有能量极高(通过光学聚焦,汇聚一点的激光能量可大于1012W/cm2)、上升时间短等显著优点,采用激光激励热电偶可获得较为理想的阶跃温升信号,保证了热电偶的均匀加热[10]。

本文中采用上升时间5μs、功率500W的大功率半导体激光器,分析了测试热电偶时间常数的理论基础,采用反馈控制激光功率的方法,产生稳定的阶跃温升信号,通过限定激光器功率大小,成功测量出OMEGA公司的4支热电偶的时间常数,为准确测量热电偶的时间常数提供参考[11-14]。

-

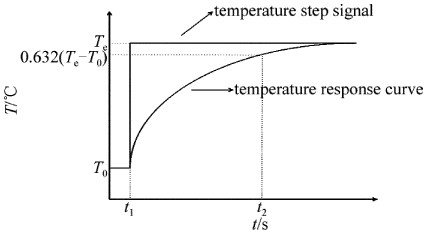

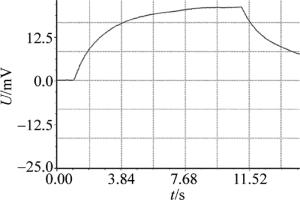

由于影响热电偶时间常数测试的因素很多且复杂,这些因素不能量化用于公式推导,因此难以用理论计算的方法获得准确的数值[15-16]。通常采用实验法得到热电偶时间常数,把热电偶传递函数按照一阶系统处理,给予一个温度阶跃信号对其进行动态测试,当热电偶吸热与散热达到一个平衡时,从响应曲线上直接获取,响应曲线如图 1所示。

图 1中,T0表示热电偶测温端初始温度,一般为环境温度;Te为阶跃温度值,热电偶测温端稳定后通过读数可知;t1表示初始温度响应时刻;t2为初始温度T0与阶跃温度Te的差值达到63.2%对应的时刻。用τ表示热电偶时间常数,是指温度达到温升阶跃量63.2%所用的时间(即τ= t2-t1)。

-

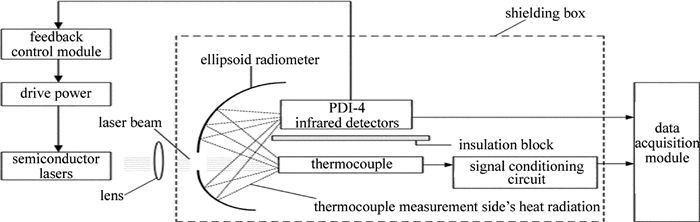

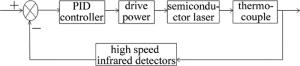

热电偶时间常数测试系统由半导体激光器产生动态阶跃温升信号,激光激励热电偶的表面,引起其表面瞬态温升,从而直接测量出热电偶的时间常数。时间常数测试系统如图 2所示。红外探测模块和被测热电偶分别置于椭球面反射镜的两个共轭焦点上,为了避免二者的直接辐射热传递,加入一个隔热块。半导体激光器输出激光经过透镜聚焦后激励被测热电偶,另一焦点上的高速红外探测模块实时检测热电偶表面温度变化,反馈控制模块根据系统输出温度和期望值温度的偏差实时调节半导体激光器驱动电源电流,以确定加热功率,获得被测热电偶温度-时间曲线,从而获得热电偶时间常数。由于高速红外探测模块的频率响应特性优于被测热电偶的频率响应特性,以前者的响应作为真值来校准后者并获得动态误差。

-

在本测试系统中,由于半导体激光器输出激光过程中功率恒定,激光输出连续,热电偶测温端随着温度升高,不仅对激光吸收效率发生变化,而且自身进行热辐射与热传导等也发生变化,造成热电偶输出经快速上升后会持续缓慢上升,停止出光后迅速下降,无法确定最后阶跃量,难以评估热电偶时间常数,热电偶输出曲线如图 3所示。

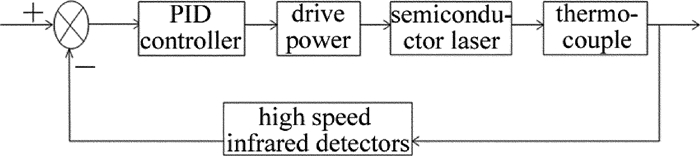

热电偶时间常数测试系统利用功率阶跃变化的激光加热被测热电偶,热电偶输出曲线会不断上升,并非温度阶跃变化,所以可通过闭环反馈控制激光功率实现温度阶跃。采用高速红外探测模块实时监测热电偶测温端表面温度变化,将探测器所得的实时探测数据反馈输入端。采用比例-积分-微分(proportion-integral-derivative, PID)闭环控制系统,跟据系统输出温度和期望值温度的偏差,通过PID控制器对系统偏差的比例微分积分作用线性加权和来消除此误差;半导体激光器输出功率与输入电流基本成线性关系,反馈控制模块根据红外探测器输入实时调节半导体激光器驱动电源的输出电流,通过控制驱动电源输出电流来线性控制半导体激光器输出功率,动态调节激光器的输出功率以确定激光器加热功率,使热电偶的表面温度以最快速度上升,达到期望的温度后,通过调节激光器驱动电流,适当降低激光器的输出功率,以实现在热电偶测温端出形成定量阶跃温度的目标,使被测热电偶得到期望的平衡温度,反馈控制过程如图 4所示。

在PID控制中,PID的参量调整是PID控制器设计的核心。实际系统由于有各种非线性,例如PID控制器的饱和非线性(对输出的限幅作用),可以较容易地观测到等幅振荡,这种振荡一般就是设定值上下的等幅振荡,根据控制经验通过对被控过程的运行特性分析从而可以确定出较理想的控制器参量。本系统中PID调试方法采用常用的扩充临界比例度法,在不用确定系统具体数学模型的情况下,经过多次实验得到系统的最佳整定参量。经过反复实验后,根据最佳的实验效果,最终确定PID反馈控制系统的参量:设置比例系数Kp=2.3,积分系数Ki=0.2以及微分系数Kd=2.4。

2.1. 热电偶时间常数测试系统

2.2. 热电偶时间常数测试系统阶跃温升信号控制方法

-

在室温12℃、湿度30%、大气压强101.325kPa的环境下对4支OMEGA公司的热电偶进行时间常数的测试,热电偶的详细参量如表 1所示。表中K表示镍铬-镍硅热电偶,J表示铁-康铜热电偶,E表示镍铬-铜镍热电偶。热电偶的实物图如图 5所示。

serial number thermocouple model indexing number range 1 KQXL-18U-6 K 0℃~1149℃ 2 TJ36-ICSS-18U-6 J 0℃~521℃ 3 TJ36-CASS-18U-6 K 0℃~899℃ 4 TJ36-CXSS-18U-6 E 0℃~521℃ Table 1. Basic parameters of thermocouple

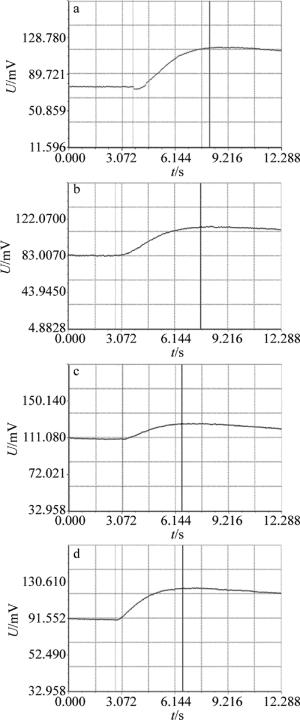

经过透镜聚焦后的半导体激光器在全量程(500W)输出时,聚焦后的激光可使热电偶温度接近2000℃,鉴于4支热电偶的测温范围,设置激光器输出功率100W,在同等条件下对KQXL-18U-6型、TJ36-ICSS-18U-6型、TJ36-CASS-18U-6型及TJ36-CXSS-18U-6型4支热电偶进行时间常数测量。热电偶测试波形如图 6所示。

在同等条件下,采用ADLINK公司的PCI8554数据采集卡,采集热电偶电压输出曲线,对测试结果进行小波降噪处理,得到热电偶时间常数曲线如图 6所示。根据以上时间常数曲线,可以得到4支热电偶的时间常数如表 2所示。

serial number thermocouple model laser power/W time constant/s 1 KQXL-18U-6 100 2.806 2 TJ36-ICSS-18U-6 100 3.094 3 TJ36-CASS-18U-6 100 2.229 4 TJ36-CXSS-18U-6 100 2.457 Table 2. Thermocouple test results

-

采用半导体激光器作为激励源,使用反馈控制激光功率的方法产生阶跃温升信号,在限定输出功率100W时,得到了热电偶时间常数曲线,从曲线直接读取出4支热电偶的时间常数。实验结果证明,热电偶时间常数测试系统可产生较理想的阶跃温升信号,控制器动态性能和抗干扰性能较好,为热电偶时间常数的测量提供了一个稳定的测试平台;实验结果为激光器高功率高温条件下对快速响应、大量程热电偶时间常数的测量和反馈控制提供了指导。

Map

Map

DownLoad:

DownLoad: