HTML

-

Ti-6Al-4V钛合金以其轻质、强度高、耐腐蚀性强等优点被广泛地应用于航天、船舶、汽车及医疗领域,服役环境苛刻[1-2]。随着其大量的应用,对高温服役环境下Ti-6Al-4V钛合金的机械性能要求越来越严格[3]。近些年,激光喷丸(laser shock peening, LSP)技术由于其一系列的优点被广泛地应用于改善金属材料的抗疲劳、耐磨损及抗腐蚀性能。当冲击波压力超过金属的动态屈服强度,材料将发生严重的塑性变形,引入残余压应力并细化表层晶粒,可有效提升金属的机械性能及抗疲劳寿命[4-6]。此外,激光喷丸还因其能够直接作用于疲劳区域被广泛地应用。

一般来说,金属材料的机械性能与其内部的微观组织具有直接的联系,但其内部微观组织又受到材料服役环境温度的影响[7]。已有的文献报道多集中在常温状态下激光喷丸对金属材料的力学性能及微观组织的影响,针对中高温条件下激光喷丸处理对钛合金力学的稳定性与微观组织热稳定性的研究还较少。因此,本文中主要对Ti-6Al-4V钛合金表面进行激光喷丸及不同温度的保温处理,从残余应力分布、表面微观硬度及微观组织结构演变等方面研究激光喷丸对中高温条件下Ti-6Al-4V钛合金机械性能的强化效果,并探究强化效果与微观组织演变间的联系。

-

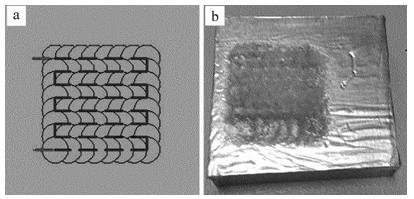

试验材料为轧制的Ti-6Al-4V钛合金板,线切割加工成25mm×25mm×8mm的试样。在激光喷丸处理前,对所有试样表面进行打磨、镜面抛光,并采用无水乙醇清洗试样表面油污。激光喷丸试验选用了江苏大学强激光实验室的高功率Nd:YAG激光器装置系统,激光喷丸参量如表 1所示。选用均匀的流动水层为约束层,0.1mm厚的铝箔为吸收层,喷丸区域大小为13.5mm×13.5mm,激光喷丸线路及处理后的试样外貌如图 1所示。

pulse energy/

Jspot diameter/

mmlaser pulse width/

nslaser frequency/

Hzlaser wavelength/

nm8 3 10 1 1064 Table 1. Parameters of laser shot peening technology

激光喷丸后,1#试样不做任何热处理,将2#试样、3#试样、4#试样和5#试样依次放入SXL系列1208型程控箱式电阻炉内分别加热至400℃, 500℃, 550℃和600℃,保温1h,出炉空冷。

-

残余应力测试采用X350A残余应力测试仪,通过化学腐蚀的方法对试样逐层减薄,以完成试样深度方向的残余应力分布测试,测试允许误差为±10MPa。测试方法采用侧倾固定ψ法,定峰方法采用交相关法;辐射Coka;衍射晶面114;ψ角分别取0°, 25°, 35°和45°;2θ扫描起始角为162°,终止角为152°,扫描步距0.1°;计数时间1.00s;X光管高压20.0kV,X光管电流5.0mA,准直管直径∅2mm。试样的显微硬度采用压入法在HXD-1000TMC/LCD型显微硬度计上测量,加载载荷1.96N,加载时间10s,多次测量取平均值。

-

利用JSM-6480型扫描电镜和JEM-2100(HR)型高分辨透射电子显微镜观测Ti-6Al-4V钛合金试样表层的微观组织。透射电镜(transmission electron microscope, TEM)制样时,需将适当大小的试样线切割成厚度大约1mm的薄片,表面清洗除油后用金相砂纸细磨至0.1mm左右厚度薄片;薄片冲孔成直径3mm的小圆片后,用凹坑减薄仪将圆片磨至20μm~30μm,丙酮浸泡清洗除胶;最后进行电解双喷减薄及离子减薄,减薄后便可观察试样薄区的微观组织。

1.1. 材料及激光喷丸参量

1.2. 残余应力及微观硬度检测

1.3. 微观组织的观测

-

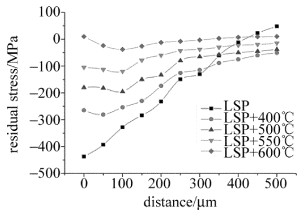

图 2为激光喷丸后的试样截面方向上的残余应力分布。由图 2可知,激光喷丸后的试样表层获得了较高的残余压应力与较大的影响层深,该现象主要由激光喷丸诱导产生的冲击波的力学效应造成。激光在吸收层与约束层的共同作用下,在靶材表面产生较高压力的冲击波,迫使材料产生屈服,造成冲击区域微塑性变形,进而导致残余应力的形成。试验结果还显示了材料表层残余应力的热释放行为,在600℃附近残余压应力释放至0MPa。有研究表明,这是因为高温下材料易发生软化,而且强化后的材料表层残余应力分布无规律[8]。激光冲击后,冲击波在材料表层造成的缺陷和微裂纹也会诱导应力释放行为。同时需要指出的是,中高温条件下残余应力在深度方向上的分布基本呈现相同趋势,即使在550℃的高温下,激光喷丸后的试样仍然具有100μm深的影响层。分析认为,残余压应力的存在,可引起裂纹的闭合效应,有效的降低疲劳裂纹扩展的驱动力,延长疲劳裂纹的扩展寿命[9-10]。

-

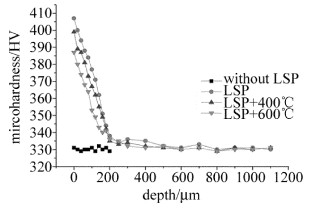

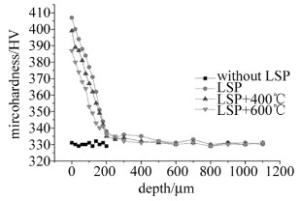

对激光喷丸处理前后的钛合金样品截面进行了微观硬度测试,试样截面微观硬度分布如图 3所示。结果表明,激光喷丸可以有效提升试样表面的微观硬度,基体硬度可由331.6HV提升至407.4HV,提高了22.8%。由霍尔-佩奇(Hall-Petch)关系式及材料的微观硬度与位错密度的关系式可知,此时的硬度提升主要由位错密度的提升和晶粒的细化导致[11]。大量的实验也表明,随着晶粒直径的减小,位错密度增大,材料的表面硬度会增加[12]。此外还对保温处理后的激光喷丸试样做了测量,不难发现,经400℃热处理1h后,试样表层硬度下降了8.3HV,经600℃热处理1h后,试样表层硬度下降了20.1HV,仍高于未经激光喷丸处理的试样,随层深的变化规律依然与未经保温处理时相同,在深度200μm左右变化趋于平缓,逐渐接近基材本身硬度。保温处理后,试样的硬度下降主要由晶粒的长大及位错密度下降所引起。

-

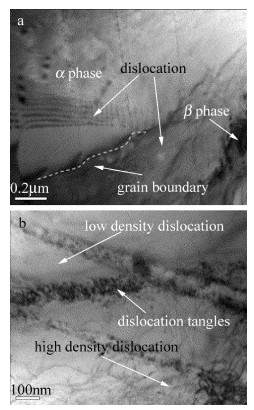

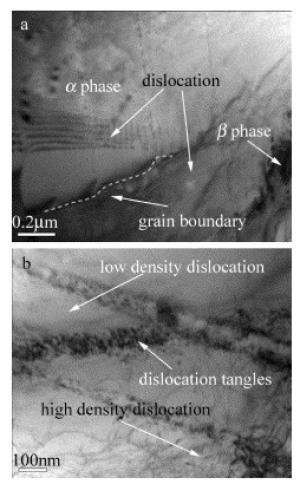

图 4所示为未经激光喷丸和激光喷丸后的Ti-6Al-4V钛合金的TEM像。从由TEM像可以清楚观察到激光喷丸前原始组织内部的α相和β相,相界清晰可辨,其中,明亮的部分为α相,发暗的为β相,两相晶体内部均无明显形变缺陷,仅α相晶界处出现少量堆垛位错线。激光喷丸处理后,试样表面产生了高应变率的塑性变形。当冲击波压力大于材料位错的均匀成核阈值时,会在冲击波阵面附近快速形成弯曲状的位错。而且,由于激光能量的不均匀分布以及不同结构对塑性变形的响应不一致,从TEM图中可看出明显的高密度位错区和低密度位错区,并在晶界处出现位错缠结。

由于激光喷丸形成的微观组织是一种非平衡结构,存在大量的非平衡晶界和晶格畸变,晶体缺陷会对材料的热稳定性造成重要的影响。高温环境下,晶界由非平衡状态向平衡态转变,引起微观组织的变化,从而影响钛合金的机械性能。因此,有必要从强化后钛合金内部微观组织变化的角度来研究钛合金高温条件下的应力释放及表面硬化的行为[13]。

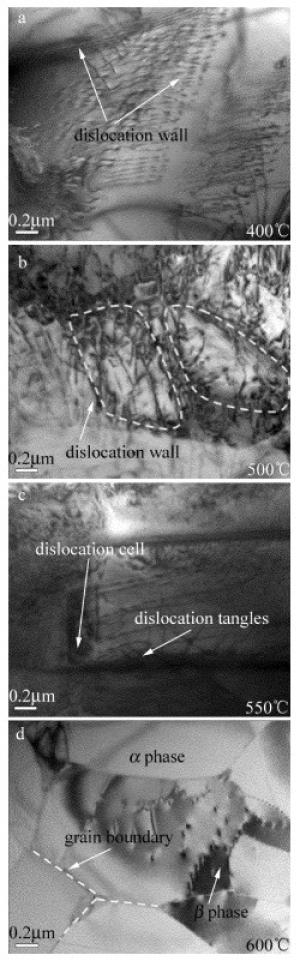

图 5所示的TEM图显示了经过不同温度保温处理后的Ti-6Al-4V钛合金内部位错的多种组态。由图 5a和图 5b可知,激光喷丸后,组织内的位错密度较高,位错线之间排列较杂乱;在400℃保温处理的情况下,高温为位错的运动提供了充足的驱动力,位错通过自身的运动进行重整、排列,异号位错彼此吸引而湮没,同号位错则整齐排列形成位错墙;随着温度进一步升高,位错墙的分割作用使得晶体内部出现部分亚晶界,晶粒得到细化。图 5c和图 5d中则显示了明显的晶粒长大过程,高温为晶界迁移提供了足够的温度条件。为获得稳定的位错形态及平衡系统内部应力,位错运动进一步加剧;温度升至600℃时,缠结在晶界处的位错随着位错运动的加速进一步重整,位错胞也逐渐消失,晶体内的位错密度也大大降低。总体来说,尽管在保温初期,晶体内会出现部分动态回复过程,但晶体尺寸的总体趋势是随着保温温度的升高而增大,晶体内的位错密度则随着温度的升高而下降。综上可知,激光喷丸在材料表层诱导产生的大量位错及高温下“位错组态演化”最终导致了高温条件下的应力释放行为[14]。

室温下,试样母材组织为初生α相和β相组成的等轴组织,其中,等轴α相作为基体,晶间β相分布在基体的边界位置,原始组织分布不均匀且相对粗大;激光喷丸后晶粒尺寸明显减小。晶粒的细化导致晶界增多,可进一步阻碍位错的运动,使位错在晶界处塞积,产生高密度位错,从而提高材料的微观硬度。图 6为激光喷丸后,不同温度下的Ti-6Al-4V试样的显微组织形貌变化。根据图 6a和图 6b可以发现,400℃~500℃温度范围内,试样的显微组织形貌基本相同。当温度达到550℃ ~ 600℃范围内时,试样的显微组织形貌发生了较大变化,两相均有颗粒粗化的现象[15],而且高的热处理温度为界迁移供应了足够多的能量,使得晶界更容易进行扩散、迁移,并借以吞噬周围细小的晶粒,晶粒数目变少,尺寸增大,如图 6c、图 6d所示。此外,由于热处理温度有限,并未能达到Ti-6Al-4V钛合金β相相变点温度[16],因而并没有明显新相的产生。总体来说,晶粒尺寸在400℃~600℃范围内呈现逐渐增大的趋势。可以推断,激光喷丸粗化了材料表层的微观组织结构,从而影响了试样的表层硬度。

2.1. 残余应力稳定性测试

2.2. 微观硬度稳定性测试

2.3. 残余应力释放及硬度提升微观机理

-

对Ti-6Al-4V钛合金进行了激光喷丸和不同温度下的热处理,从残余应力分布、微观硬度和微观组织演变方面讨论了激光喷丸对Ti-6Al-4V钛合金强化机理。

(1) 激光喷丸显著提高了Ti-6Al-4V钛合金表面残余应力,且在不同温度下会发生不同程度的应力松弛。

(2) 激光喷丸可以有效提高Ti-6Al-4V钛合金表面微观硬度,且室温下强化效果尤为明显。室温阶段,位错强化与细晶强化是主要的强化机理;中高温阶段,随着位错密度的下降及晶粒长大,材料的硬度稍有下降。

(3) 激光喷丸是诱导中高温条件下Ti-6Al-4V钛合金产生微观演变的主要原因。激光喷丸区域组织内产生大量位错,并随着温度升高出现位错线、位错墙、位错缠结、位错胞等多种组态,晶粒尺寸总体呈现增大趋势。以上现象可以被用来从微观角度解释中高温条件下Ti-6Al-4V钛合金发生应力松弛及微观硬度变化等机理。

Map

Map

DownLoad:

DownLoad: