HTML

-

随着光电技术的发展,CCD作为一种图像传感器,以其体积小、数字化、速度快、寿命长等优点[1],已成为电视跟踪、光电成像、光电观瞄等系统的重要组成部分。由于CCD是一种弱光成像器件,在受到激光光源辐照时,一方面激光使CCD光敏单元的光电转换达到饱和,使成像受到干扰;另一方面激光在与组成CCD材料的作用过程中,会造成不可逆的损伤破坏[2]。因此,研究激光辐照CCD的温度分布与应力分布对丰富激光损伤机理数据库以及改善CCD抗激光加固措施[3],从而制造成相应的激光压制武器及激光防护装置有着重要意义。

激光辐照会造成CCD光饱和、灵敏度退化、伏安特性曲线变直及暗电流产生等光学、电学性能下降的软破坏[4-7]。而更严重的是,激光辐照产生的热学效应及力学效应会使CCD的组成材料及结构发生不可逆的硬破坏[8-11],致使CCD永久失效。针对这方面的研究,国内外已有很多报道,主要方法分为实验研究和仿真研究两种。在仿真研究中,大多数学者认为CCD受激光辐照时,金属遮光层和感光层均与激光发生作用[3, 12],忽略了微透镜对激光辐照位置的影响;并且,在仿真中将CCD的各面作为自由边界处理,忽略了真实环境中基底要固定的实际情况;计算过程中,忽略了热传导及热辐射,热辐射是关于靶材温度4次方的函数,在靶材温度逐渐升高的过程中,热辐射对靶材温度的影响会越来越大。

本文中由激光辐照的实际位置出发,建立了热力耦合模型。以波长为1.06μm、功率0.5W的连续激光辐照CCD进行仿真研究,首次将热辐射、热对流及固定约束等实际条件纳入到激光对CCD辐照的仿真中,依据仿真结果,讨论了CCD的硬破坏机理。

-

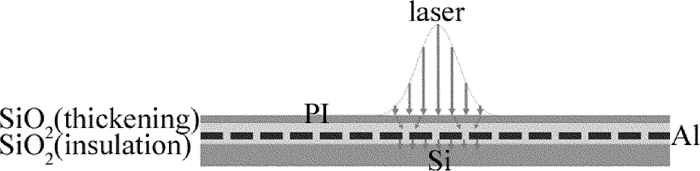

CCD按入射光线方向组成材料依次为微透镜、SiO2增厚层、金属遮光Al膜层、SiO2绝缘层、基底Si[13]。构成微透镜的主要材料为聚酰亚胺(polyimide,PI),材料PI及SiO2对1.06μm的激光吸收率几乎为0,全部光能被微透镜通过金属层开口聚焦到基底Si表面,金属层不受激光辐照。基底Si对1.06μm的激光有较强的吸收率η=67%,因此可以将激光辐照CCD看成是CCD基底Si上加了一个热源。基于这种思想,对CCD进行简化,并进行理论分析与仿真。将CCD简化为圆形结构靶材,如图 1所示。

-

假设各层材料均为各向同性均匀,热传导和热弹性耦合的基本方程组可描述为[3]:

式中, Tj为第j层材料在t时刻的温度分布;ρj,cj,κj和Dj分别表示材料的密度、比热容、导热系数和热扩散率;Qj是体热源,表示激光作用下材料所吸收的激光能量;urj和uzj分别表示位移在径向和轴向上的分量;εj, μj, βj分别表示体应变、泊松比和材料的热膨胀系数;j=PI,Ot,M,Oi,Si, 分别表示微透镜、SiO2增厚层、金属遮光层、SiO2绝缘膜层、基底Si。其中Qj可以表示成以下形式[14]。

(1) 当为基底Si层时,激光能量在Si表面被吸收,可简化看成基底Si层上表面有一热源,这样QSi就可改为边界条件中面热源来表示:

式中, ηSi表示基底Si对激光的吸收率,I0表示激光光斑中心的功率密度,w表示高斯光斑的束腰半径,r表示考察点到光斑中心的径向距离。

(2) 当为其它层时,热量是从基底Si层上表面热传导来的,因此对应的边界条件为:

式中, hj(j=Si, Oi, M, Ot, PI)表示各层材料的厚度,K表示外表面和空气的对流传热系数,αPI为微透镜的发射率,σ为黑体辐射常数,Tair为环境温度。为了得到激光辐照CCD的温度场及应力场,采用有限元法能有效地处理各种复杂边界条件。

1.1. 物理模型

1.2. 理论公式

-

根据上述理论模型,使用波长为1.06μm、功率0.5W的连续激光对CCD进行照射,光斑半径a=1mm,光斑的功率密度分布如图 2所示。初始环境温度Tair=300K,CCD底部为固定约束,并假设底部绝热,四周与空气形成对流,对流传热系数K=5W/(m2·K)。激光辐照下,把CCD内各材料间的辐射换热看成是热传导的一部分,而设CCD向外界辐射换热主要由最上层上表面进行,且辐射能量主要集中在红外波段,忽略其它波段的辐射能量损失。当激光辐照开始时,主要由微透镜上表面进行辐射换热,当微透镜层达到一定温度发生热分解后,辐射换热由SiO2增厚层上表面与环境进行。组成CCD的各种材料参量见表 1。

parameter PI Al SiO2 Si density ρj/ (kg·m-3) 1.53×103 2.7×103 2.64×103 2.52×103 thermal conductivity κj/(W·m-1·K-1) 0.12 238 1.3 156 melting point Tm, j/℃ 500(pyrolysis) 660 1700 1412 specific heat capacity cj/(J·kg-1·K-1) 1.09×103 1.05×103 841 1009 thermal expansion coefficient βj/K-1 2×10-5 2.29×10-5 5×10-7 2×10-5 Young’s modulus Ej/Pa 4×109 1.38×1011 8.7×1010 1.07×1011 Poisson’s ratio μj 0.3 0.33 0.16 0.28 thickness hj/μm 2 1 thickening 3.2 insulation 0.2 30 radius rj/mm 2.4 2.4 2.4 2.4 emissivity αj 0.521 — 0.985 — absorption rate of 1.06μm laser ηj — 0.06 — 0.67 -

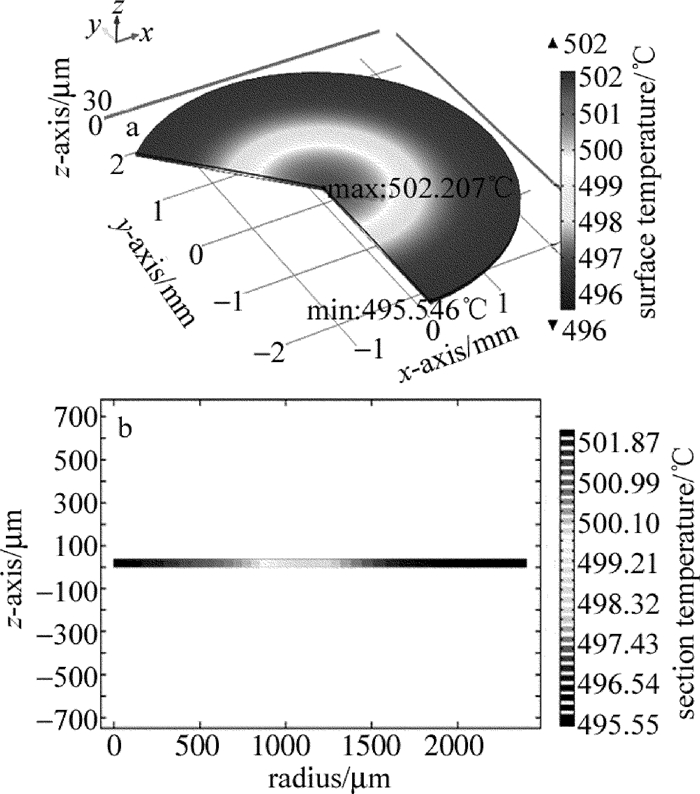

图 3为CCD在激光辐照时刻t=3.4s时的温度分布图。由图可知,温升从激光光斑中心向靶材边缘递减,而沿轴向变化不大,沿径向有大约6℃的温差。因此,研究CCD的热损伤时可以计算CCD的平均温度。

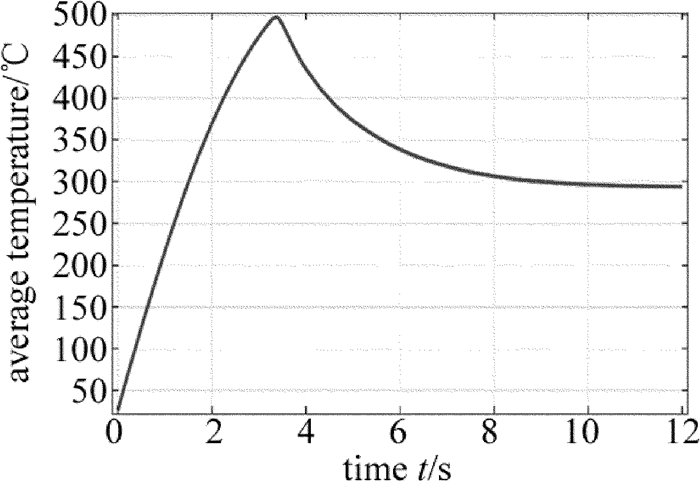

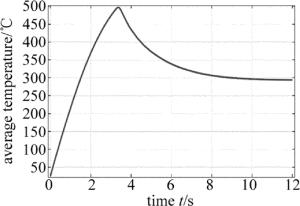

图 4为CCD的平均温度与辐照时间的关系。由图可知,随着辐照时间的增加,温升逐渐增加,但是增速逐渐趋缓。这是因为随着CCD整体的温度升高,辐射换热量也逐渐增大,能量损耗的加大使温度曲线呈现为“上凸”式上升,当t=3.4s,CCD温度达到500℃,微透镜热分解,假设PI全部分解,忽略其分解作用时间。微透镜分解后聚光效应消失,激光透过SiO2增厚层照射到遮光Al膜上,一般Al膜开口率30%,也就是说激光能量的70%作用在Al膜上,其余30%继续作用在基底Si上。由于Al膜对该波段激光吸收率仅6%,激光的大部分能量被反射,CCD中整体的输入热源大幅降低,再加上SiO2增厚层的热辐射系数比PI高很多,所以温度曲线呈现“下凹”式走低,最终达到热输入和热损失相等的平衡,温度维持在295℃。通过温度场的仿真可以发现,功率0.5W、光斑半径1mm的连续激光对该CCD造成的热破坏是使微透镜热分解,其它材料因达不到熔点而未受熔融损伤。

-

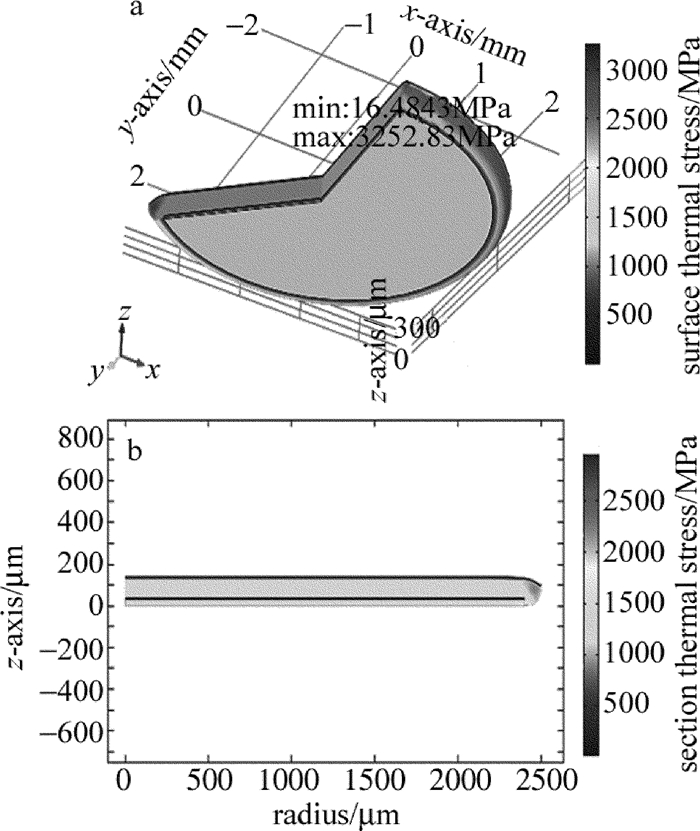

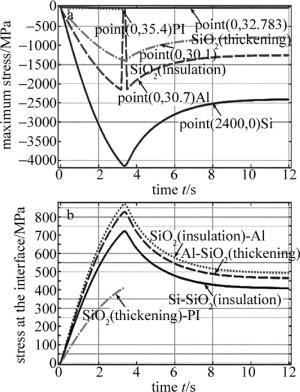

图 5为CCD在激光辐照时刻t=3.4s时的应力及应变分布图。由图可知,在CCD的多层材料中,遮光Al膜层和基底Si层所受应力较大。图最大应力出现在基底Si下表面边缘处,由于是固定边界与自由边界的交汇处,受到CCD因温升而发生向上和向外的热膨胀所引起的应力同时作用。最小应力出现在SiO2增厚层的边缘。因此,判断CCD热应力破坏的位置应着重考虑基底Si下表面边缘处。

图 6a和图 6b分别表示材料内部最大的应力及材料交界面的应力随时间的变化。由图可知,CCD中各材料受到的最大应力均为压应力,主要是受热膨胀所致。其中以Si下表面边缘处所受应力最大,峰值达到4140MPa,可是Si的抗压强度有限,为120MPa[3],也就是说当激光作用0.1s左右时,基底Si固定边缘就出现了滑移,随着辐照时间增加,滑移位置向中心移动。由图 6b可知,材料交界面处以遮光Al膜与上下层的SiO2膜层间的拉应力为最大。由于Al膜和SiO2的附着力为100MPa左右[12],所以当激光作用0.3s时,由光斑中心开始,遮光Al膜和SiO2膜层发生分离,并向边缘扩散。

-

经以上分析,激光辐照首先使基底Si在固定底面边缘产生沿径向由外向内的滑移,紧接着遮光Al膜与SiO2膜层沿径向由内向外脱离,两种应力破坏可能伴随发生。遮光Al膜的脱离致使产生漏光现象,并且减少基底Si的向上热传导,减小了热量损失,加快了基底Si与固定底面的滑移分离。当基底Si完全脱落,离开光学系统的像面,整个系统将失效。

2.1. 激光参量和材料参量

2.2. 温度场的仿真与分析

2.3. 应力场的仿真与分析

2.4. 破坏机理的讨论

-

激光对CCD的破坏主要是对其组成材料的熔融破坏和应力破坏。由分析可知,功率为0.5W的1.06μm连续激光以光斑半径1mm对CCD进行照射,在热破坏方面,微透镜PI将在激光辐照3.4s时, 首先达到阈值发生热分解作用,并且这种分解会使激光作用位置发生变化,加之存在热辐射和热对流等能量损失,各主要材料温度达不到熔点而不受熔融破坏;在应力破坏方面,基底Si因压应力达到材料强度,在激光辐照0.1s时, 开始在固定底面的边缘产生由外向内的滑移。随后,金属Al膜因交界面应力达到附着力的量级而发生脱离。由于应力破坏发生在热破坏之前,而且Al膜的脱离可能使热破坏终止,甚至不发生,但是对应力破坏起到加速作用。因此,应力破坏成为该型激光对CCD损伤的原因。最终,CCD会因整个器件脱离固定位置而导致系统失效。

Map

Map

DownLoad:

DownLoad: