HTML

-

钢化玻璃是平板玻璃经加热淬冷处理后形成的,具有抗弯、承载能力强、破裂后无锐角、抗热炸裂等优点[1-2]。其广泛应用于航天飞行器、武器装备、汽车挡风玻璃、电子产品屏幕、高层建筑门窗、家具等[3-5]。由于钢化玻璃具有极高的硬脆性,在激光切割过程中会产生很大的热应力,导致裂纹产生并发生破裂[6-8]。英国SALMAN[9]借助有限元软件ABAQUS分析了激光切割速度对应力的影响,并优化了切割路径。TSAI[10]在用CO2激光切割LCD玻璃时利用应力诱导材料沿切割方向分离,并分析了裂纹的形成机理。浙江工业大学WANG等人[11]采用CO2激光在液晶玻璃基板上预置初始裂纹, 用CO2激光作为热源对其进行加热并用Ar气进行冷却。陕西理工学院HOU等人[12]采用仿真分析法和对比试验法对飞机蒙皮材料的疲劳性能进行了理论分析和实验验证,研究了激光切割对飞机机身蒙皮材料疲劳性能的影响。结果表明, 激光切割对飞机机身蒙皮材料疲劳性能有一定的影响,但通过切缝打磨处理会提高其疲劳寿命。本文中将特定波长的会焦激光束导入高速流动的水束,使激光在水与空气界面发生多次全反射后形成横截面能量均匀分布的高能束射到工件上,与工件材料、水发生复杂的热、力等物理和化学作用以实现切割,可有效弥补目前金刚石切割钢化玻璃的不足。

-

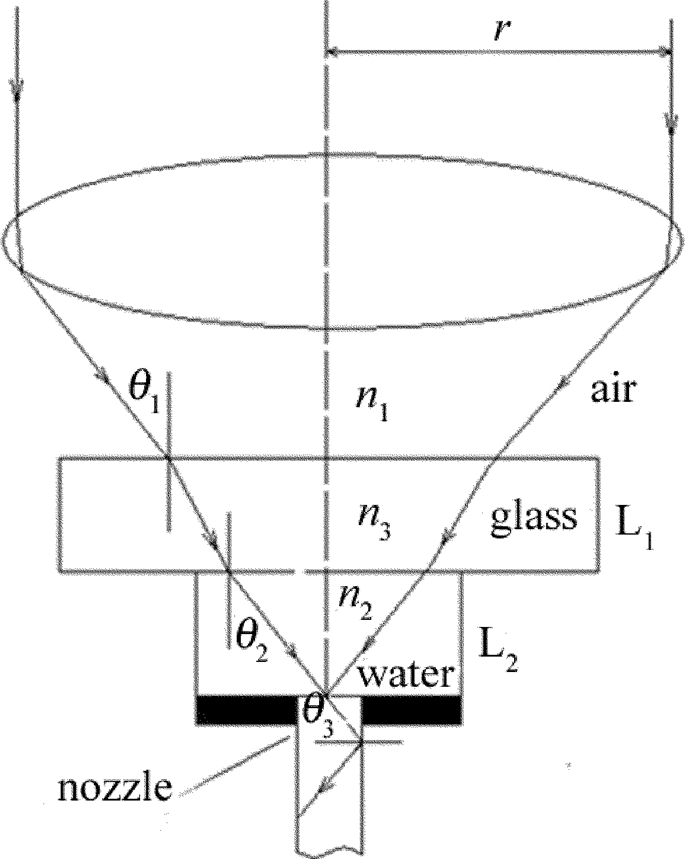

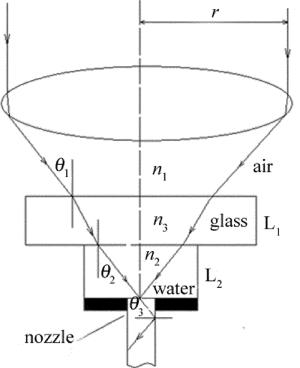

激光耦合即激光束在微水束中发生多次全反射后形成高能量束并在微水束中传输的过程。耦合期间激光束要依次经过空气层、玻璃层L1、水层L2并进入到水束光纤的开始端[13-14],如图 1所示。

激光光束在水束中发生全反射的条件是入射角θ1不大于最大入射角αmax。由于在耦合过程中,玻璃厚度很薄,假设光线在经由玻璃层时是直线传输,则发生临界全反射时,有:

由图 1可得:

由(1)式~(4)式,得到:

式中, n1为激光在空气中的折射率,n2为激光在水中的折射率,C为临界入射角,r为激光束聚焦前的光斑半径,H0为凸透镜焦距。当n1=1,n2=1.33时,由(6)式得到:θ1, max=61.3°。本文中选用r=10mm,H0=50mm,则实际入射角θ1=11.5° < θ1, max,满足激光束全反射的条件。

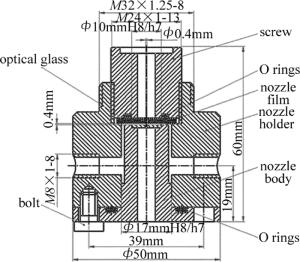

第2个重要耦合条件是微水束的稳定性。受水束内外紊乱、水束表面张力、水束速度分布以及周围空气的影响,水束的表面高度呈周期性波动[15],一旦表面波动的振幅超过极限值,被导引的激光将从水束中发散出来。本文中采用FLUENT软件对注水口数量、耦合腔顶部薄水层压力、耦合器内部流体压力对喷嘴水射流稳定性的影响进行数值分析,保证喷嘴小孔喷射出的微水束射流均匀稳定,破碎长度大。

-

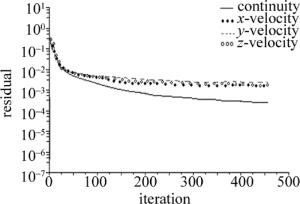

耦合腔采用Pro/Engineer进行3维建模,并用GAMBIT软件进行网格划分,网格划分采用Tri-Quad自动生成网格。划分网格后,设置边界,并输出网格文件。用FLUENT软件打开此网格文件,并设计各个参量、求解器及初始条件等,然后进行求解。为了对比不同的注水方式对微水导激光切割质量的影响,进而优化耦合装置的结构,论文依次做了单注水口、双注水口和四注水口的水流场数值模拟。

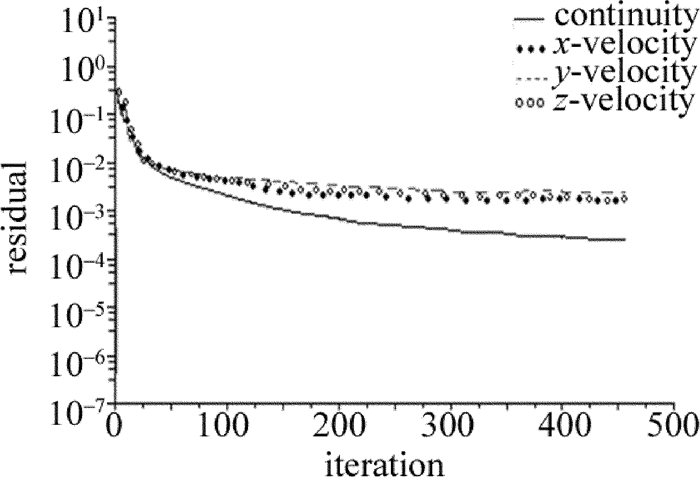

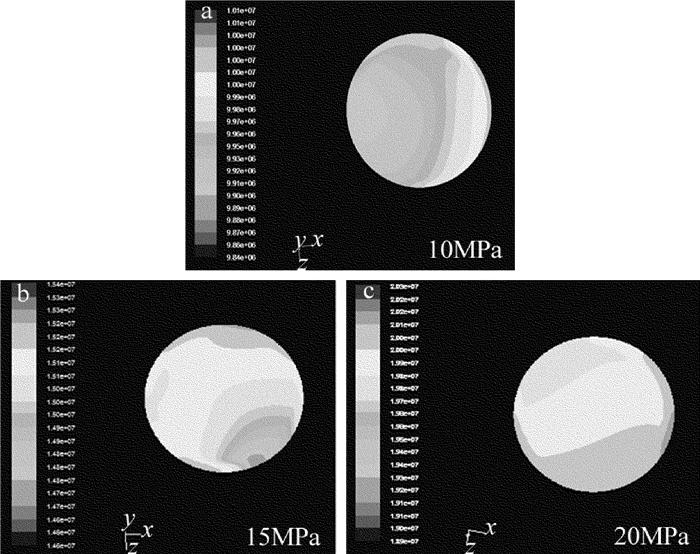

首先是残差图的收敛计算,设计的收敛参量为1×10-3。图 4为残差图的收敛计算结果,横坐标为迭代次数,纵坐标为残差值的大小。图 5为单注水口耦合腔顶部水流入口压力分布图,纵坐标为水束压力大小(MPa)。由图 5可以看出:当水束压力为10MPa时,水流入口处压力分布极为不均匀,具有明显的各向异性,且注水口一侧的压力明显较大;随着水束压力的不断增大,水束压力的各向异性逐渐减弱,在水束压力达到20MPa时,入口的水压趋近均匀。

-

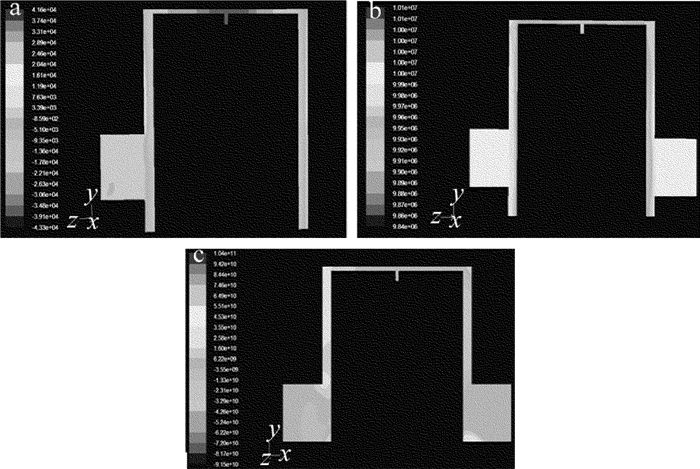

由于单注水口耦合腔得到的水流场并不均匀,注水口的开口位置对顶端薄水层水压的影响较显著,进而影响切割质量。根据流体力学原理,注水口需要对称分布。鉴于此,本文中设计了双注水口的耦合腔和四注水口进行对比优化。其耦合腔流场分别如图 6所示。

通过对比单注水口、双注水口以及四注水口的水流场数值模拟结果发现,双注水口的压力分布比单注水口的压力分布更均匀,即水流场更为稳定,利于水束与激光束的耦合;四注水口比也双注水口得到的流场稳定,从而验证了耦合装置的理论设计。

-

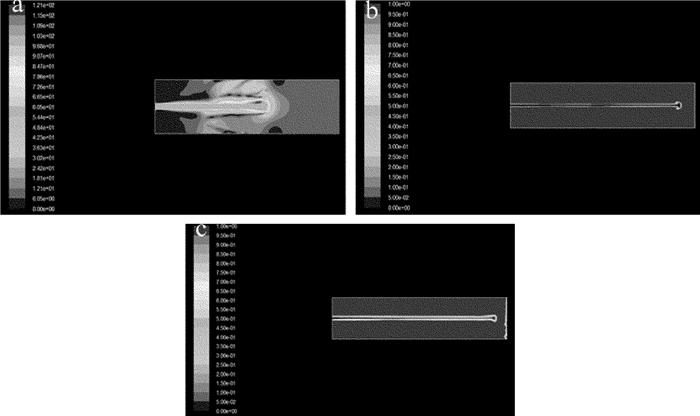

经光液耦合后的水束喷射到空气中的情况是比较复杂的。水束会在喷口处发生缩流,水束会突然缩小为原来的80%,然后水束在空气压力的作用下,其直径又慢慢变大,最终导致激光束从水束中逃逸。喷嘴口的大小和水束的流速均会影响喷射流长度,本次仿真选取水束压力为20MPa,依次对0.3mm, 0.4mm及0.5mm 3种口径喷嘴射出的水束稳定性进行仿真,如图 7所示。本次仿真设置的边界为100mm。

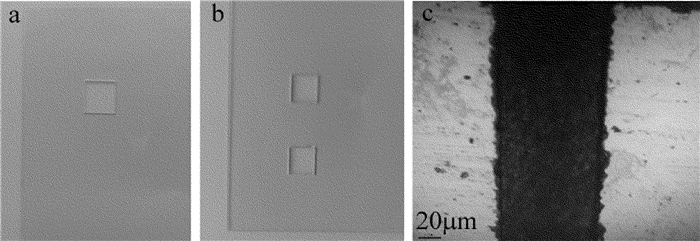

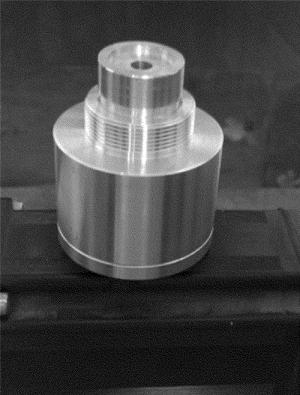

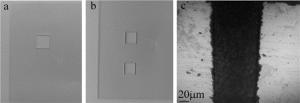

仿真结果显示:喷嘴口径越大,水束射流的破碎长度越大,但激光微水束切缝宽度也将越大。在水束压力为20MPa时,口径0.3mm的喷嘴的有效破碎长度约为60mm,口径0.4mm的喷嘴的破碎长度约为80mm,口径0.5mm的喷嘴的破碎长度达到90mm左右。综合考虑各因素,选取喷口口径为0.4mm、水束压力为20MPa、紫外激光功率为48W、重复频率为100kHz,分别对0.5mm及1.0mm厚的钢化玻璃进行微水导激光切割实验验证,切割速率为20mm/s。实验结果显示,厚度为0.5mm及1.0mm的玻璃试样的切割表面均比较光滑、基体内无微裂纹存在,切缝宽度约为100μm,但1.0mm厚的玻璃试样切割边缘有毛刺及崩边现象出现(如图 8所示)。图 9为在实验室已有的HT-3P激光加工系统上进行了一定改造,搭载YPP300光纤激光器,并配置了光液耦合装置。

3.1. 耦合腔顶部激光入射口的压力分布

3.2. 耦合腔内整体压力分布

3.3. 喷嘴水射流稳定性仿真

-

(1) 水压在10MPa~20MPa之间时,薄水层的压力分布随着进水压力的上升而逐渐变得均匀,但是它的水压不够均匀的情况并没有得到根本的改变。水射流仿真时,0.4mm和0.5mm喷嘴得到的射流破碎长度较长,喷嘴越大,水射流长度就越长,但是在达到加工工件的长度要求的情况下,尽量使喷嘴口径最小。

(2) 在喷口口径为0.4mm、水束压力为20MPa、激光功率为48W、切割速率为20mm/s时进行玻璃的微水导激光切割。厚度为0.5mm及1.0mm的玻璃试样的切割表面均比较光滑、基体内无微裂纹存在,切缝宽度约为100μm,但1.0mm厚的玻璃试样切割边缘有毛刺及崩边现象出现。

Map

Map

DownLoad:

DownLoad: